RWC 030-100 |

RWC 030-200 |

RWC 030 - 200 -400

- Description

- DATA SHEET

- Operation

- MACHINE-DIAGRAM

RWC 030 - 200 und 400

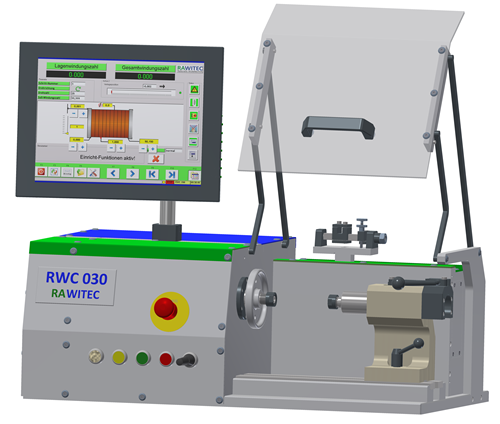

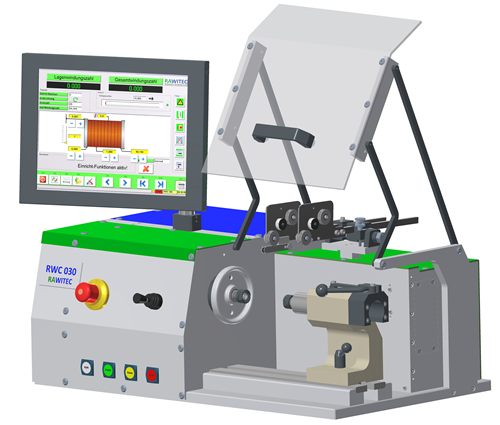

The RWC 030 is suitable for small coils and medium sized coils and thin wires, which are wound with tailstock.

The machine can be supplied with different Traverse units (200 mm and 400 mm) and center heights.

Quality and flexibility = best customer benefits.

• Easy programming.

• External programming possible with Excel and WiDaMa (Winding-Machine Data Management).

• Central program management on file servers.

• All winding parameters are programmable and extensible.

• Programmable winding operations.

• An operating step includes all needed winding parameters.

• Corrections of programmed functions during winding process.

Speed and torque of the machine can be modified very easily by changing belt and gear wheels.

Loading of winding programs takes place via USB and LAN interface.

Integrated Flash Memory serves also as a winding program and parameter data medium.

Winding programs and parameters can be created directly at the machine and edited, protected by the various password levels.

Winding programs can be edited on external Computer with Excel and transferred to the machine via USB or LAN Interface.

RWC machines have by default a 15-inch touch screen with user interface, simple and easily understandable.

RWC machines have a powerful control / real- time operating system, which is modularly extensible.

The machine can be supplied with different Traverse units (200 mm and 400 mm) and center heights.

Quality and flexibility = best customer benefits.

• Easy programming.

• External programming possible with Excel and WiDaMa (Winding-Machine Data Management).

• Central program management on file servers.

• All winding parameters are programmable and extensible.

• Programmable winding operations.

• An operating step includes all needed winding parameters.

• Corrections of programmed functions during winding process.

Speed and torque of the machine can be modified very easily by changing belt and gear wheels.

Loading of winding programs takes place via USB and LAN interface.

Integrated Flash Memory serves also as a winding program and parameter data medium.

Winding programs and parameters can be created directly at the machine and edited, protected by the various password levels.

Winding programs can be edited on external Computer with Excel and transferred to the machine via USB or LAN Interface.

RWC machines have by default a 15-inch touch screen with user interface, simple and easily understandable.

RWC machines have a powerful control / real- time operating system, which is modularly extensible.

Quality - Made in Germany

| Technical data | ||||

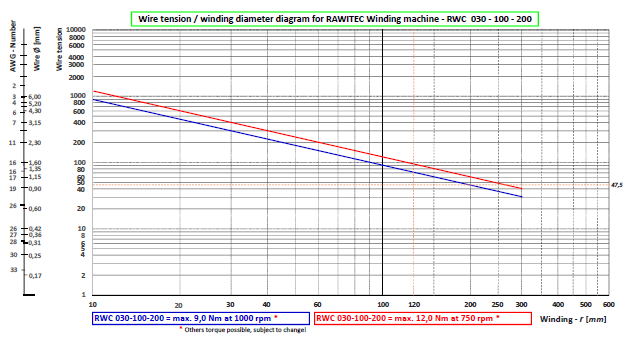

| Machine Types | RWC 030-100 * | RWC 030-200 * | ||

| Wire range | mm | 0,01 - 2,0 | 0,01 - 2,0 | |

| Winding width | mm | 100 mm * | 200 mm * | |

| Clamping length with Tailstock | mm | 125 mm * | 225 mm * | |

| max. Pitch- Traverse | mm | 99,99 /Spindle-Turn ³ | 99,99 /Spindle-Turn ³ | |

| Belt level | 5 | 0 ... 4 | 0 ... 4 | |

| Belt level 0 - rotation speed | rpm | max 750 / 1000 ** | max 750 / 1000 ** | |

| Belt level 0 - Torque | Nm | max 12,0 / 9,00 | max 12,0 / 9,00 | |

| Belt level 1 - rotation speed | rpm | max 1500 / 2000 ** | max 1500 / 2000 ** | |

| Belt level 1 - Torque | Nm | max 6,0 / 4,51 | max 6,0 / 4,51 | |

| Belt level 2 - rotation speed | rpm | max 3000 / 4000 ** | max 3000 / 4000 ** | |

| Belt level 2 - Torque | Nm | max 3,0/ 2,25 | max 3,0/ 2,25 | |

| Belt level 3 - rotation speed | rpm | max 6000 / 8.000 ** | max 6000 / 8000 ** | |

| Belt level 3 - Torque | Nm | max 1,50 / 1,12 | max 1,50 / 1,12 | |

| Belt level 4 - rotation speed | rpm | max.12000 / 16000 ** | max.12000 / 16000 ** | |

| Belt level 4 - Torque | Nm | max 0,75 / 0,56 | max 0,75 / 0,56 | |

| Spindle-/Tailstock Center height | mm | 140 * | 140 * | |

| Winding diameter | mm | 250 * | 250 * | |

| PC-Control | Industrial-PC with Single-Core-Processor, Dual-Core-Processor ** | |||

| Languages | DE, EN, IT, FR, ES, CS, HU, SU, RU, PL, NL | |||

| Connections | 2x USB2.0, 1x Ethernet (RJ45) 100M, 2x Serial (RS232), 1x VGA, 1x Foot Control Device, Digital I/O, 2x PS2 | |||

| OS | Robust real-time operating system | |||

| Data-Backup / Update | via USB and Ethernet | |||

| Printer connection (Optionally) | USB/Parallel ** | |||

| Digital-Analog I/O (Optionally) | expandable *** | |||

| Display | 15" Touch-Screen (metal case) Standard *, 12.1'' IP65 Touch-Monitor **, 15'' IP65 Touch-Monitor ** | |||

| Keyboard | USB Wireless Keyboard 2,4 GHz ** | |||

| Disk | Flash Memory, Local ca. 5.000 winding programs ², Network ca.20.000 winding programs *** |

|||

| Extensions | Programmable PLC interface to control external components possible (integrated) ** | |||

| Joystick | Teachfunction / Spindle to CW/CCW and Traverse (left and right) operated manually | |||

| Connection values | kVA | 1,1 | 1,1 | |

| Machine dimensions W x L x H | 510 x 765 x 660 | 510 x 765 x 660 | ||

| Power Supply | 230V - 50Hz / 16 A | |||

| Weight | ca. 85 kg | ca. 85 kg | ||

* Other dimensions possible, subject to change!

** Optionally, on request

*** Expandable on request

² In average size of 400 kilobytes (about 500 steps) Incl. comments

³ The following applies Product of speed Main spindle x Feed motion <3600 / min

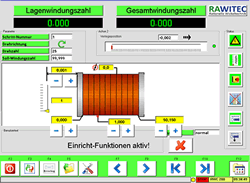

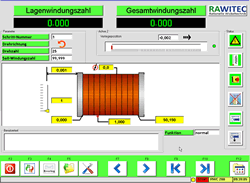

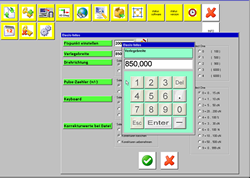

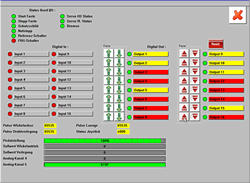

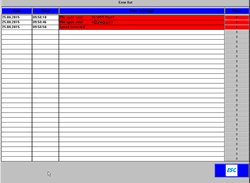

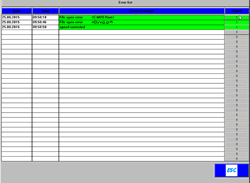

Versatile Touch Software for Winding Machine

The user interface is a simple touch screen operation optimized for winding machines and provides basic functionalities such as winding programs

Open/Close/Copy/Save/Delete /Edit/Print, also language-switch and additional functionalities from the area, configuration, service and system optimization available.

Main winding parameters |

Main winding parameters |

Machine-Settings |

IO-Config-Forcing |

Error Messages |

Error correction |

Language switching |

SYSTEM-UPDATE |

.

Do you want to have more pictures of user interface, then contact us:

CONTACT US

CONTACT US

- You are here:

-

Home

- RWC 030-200-300-EN