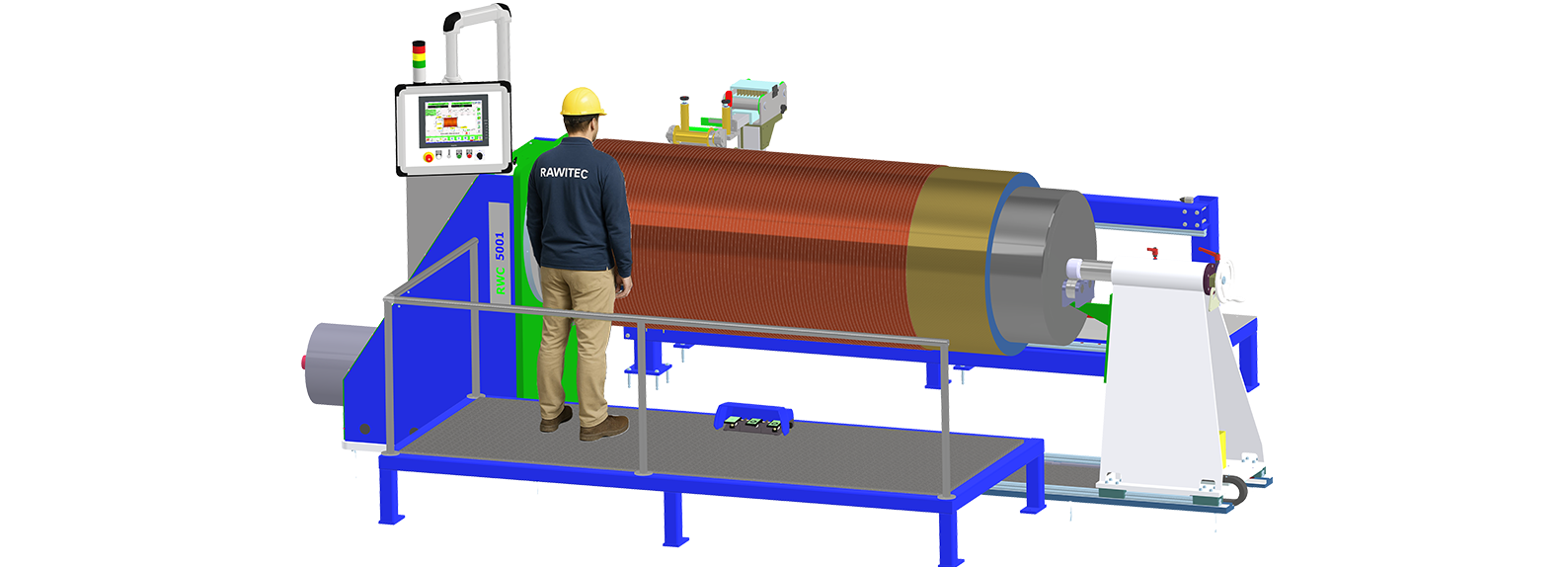

RWC 5001 – Robust winding technology for thick wires and large coils

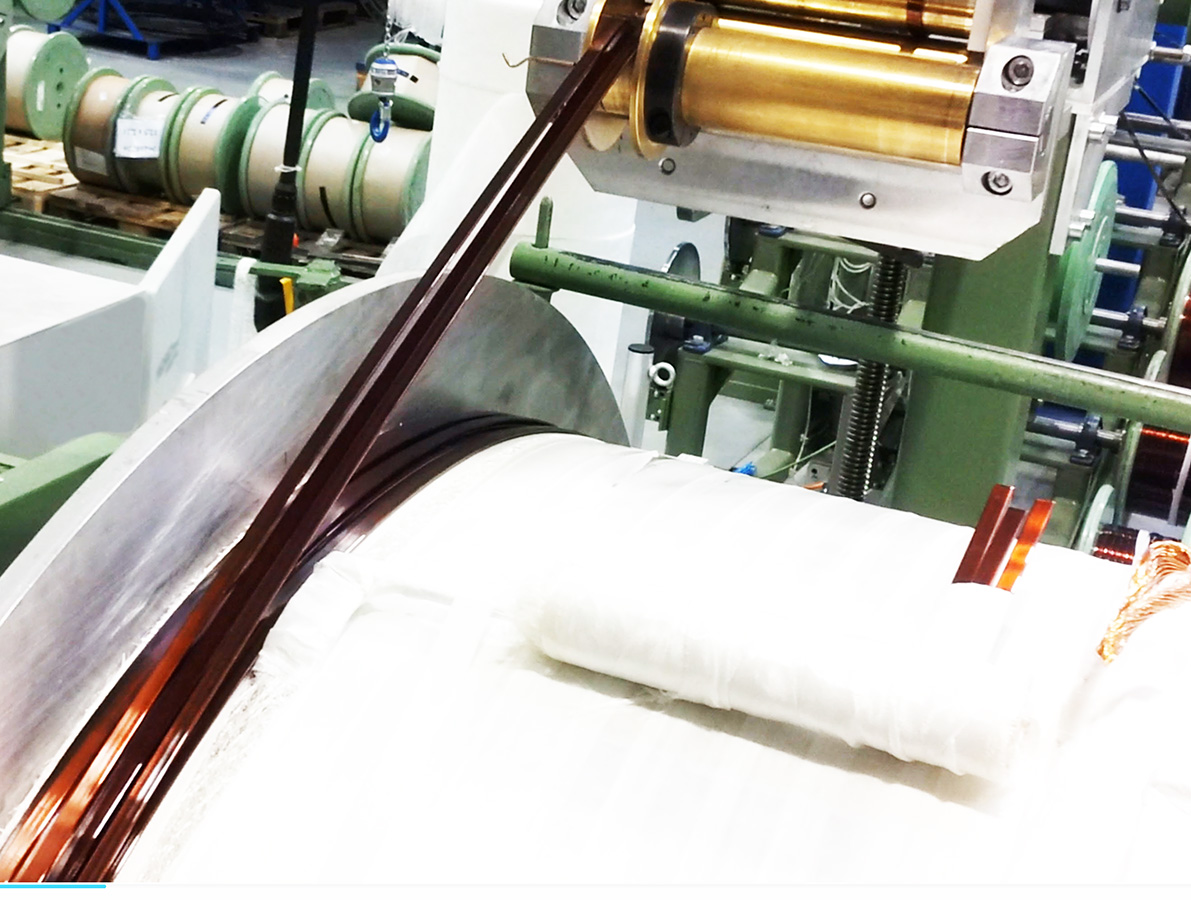

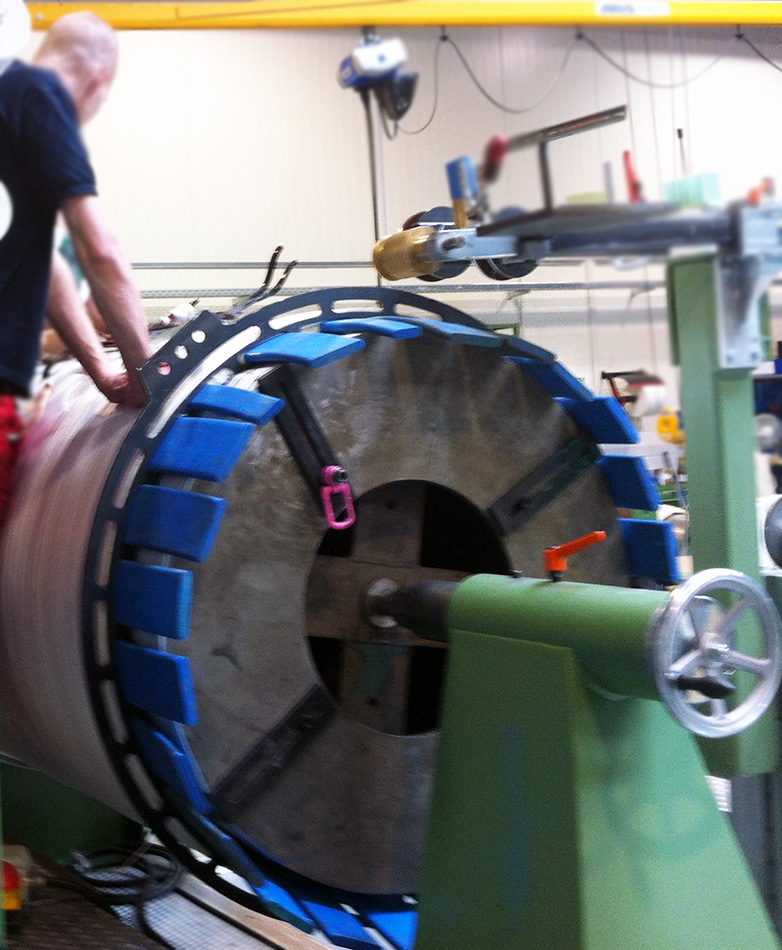

The RWC 5001 is our high-performance winding machine for industrial applications involving very large coils and high torque demands. It processes massive round and flat wires up to 250 mm² and is suitable for both single and series production in transformer and energy technology.

🌐 Versatility & Adaptability

- Suitable for: Thick wires up to 250 mm², round and rectangular cross-sections

- Coil bodies: Round or rectangular, with or without air cooling channels

- Traverse width: Up to 4000 mm depending on type

- Center distance: Clamping length up to 4150 mm

- Max. coil diameter: 1400 mm

🔧 Mechanical Features

- Gear rim drive: With fixed reduction for high torques

- Torque: Up to 12,000 Nm

- Spindle speed: Up to 60 rpm

- Stable machine base: For coil weights up to approx. 3.5 tons

💡 Control & Operation

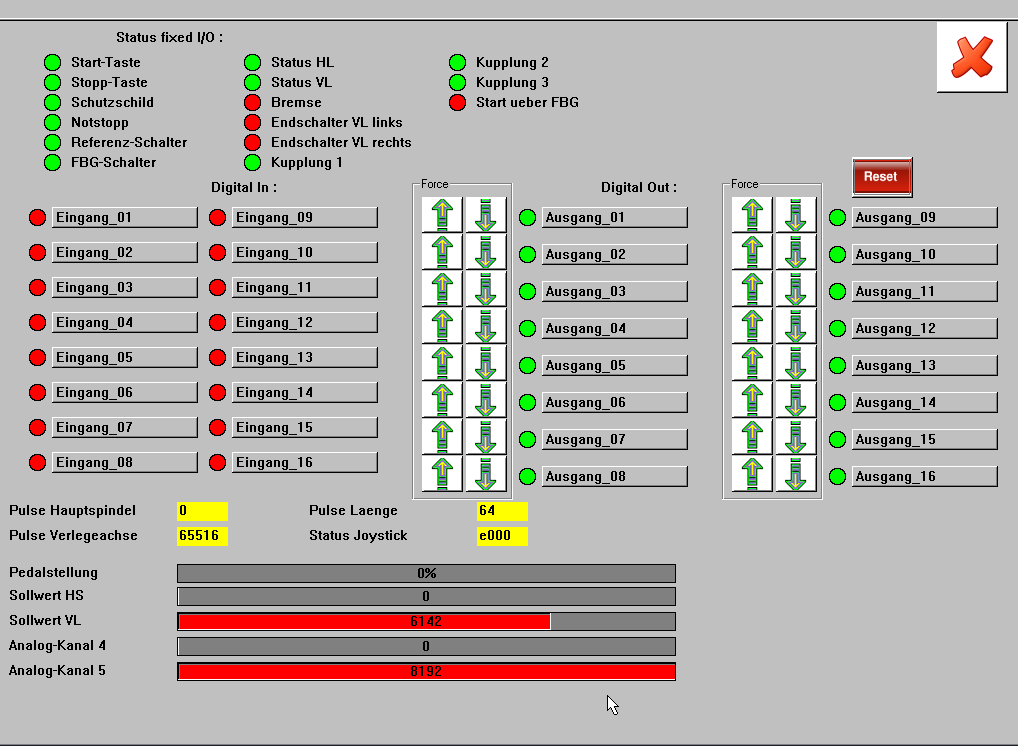

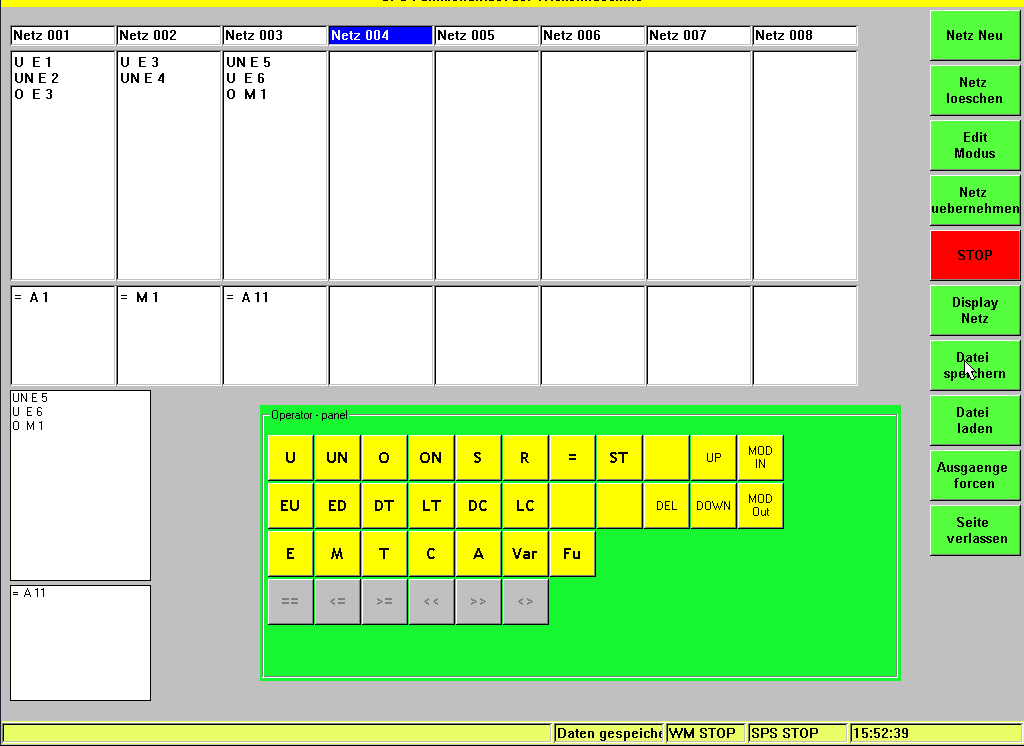

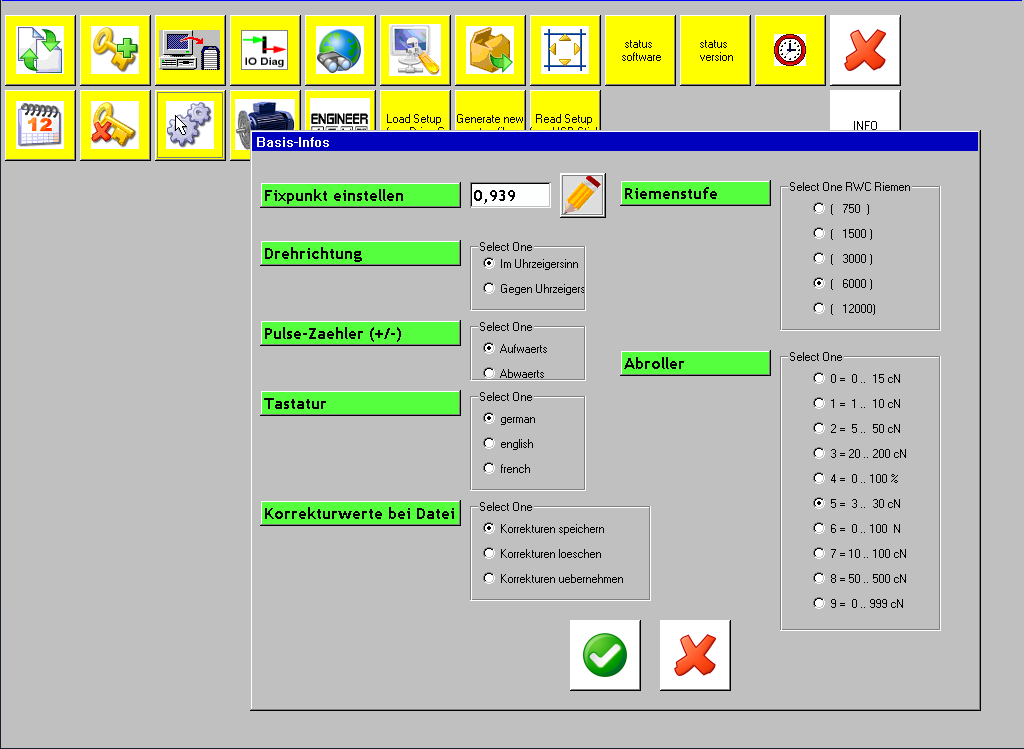

- Industrial PC: With real-time operating system and touch control

- Teach function: For manual control of spindle and traverse axis

- Program creation: via Excel, RAWITEC editor or WiDaMa system

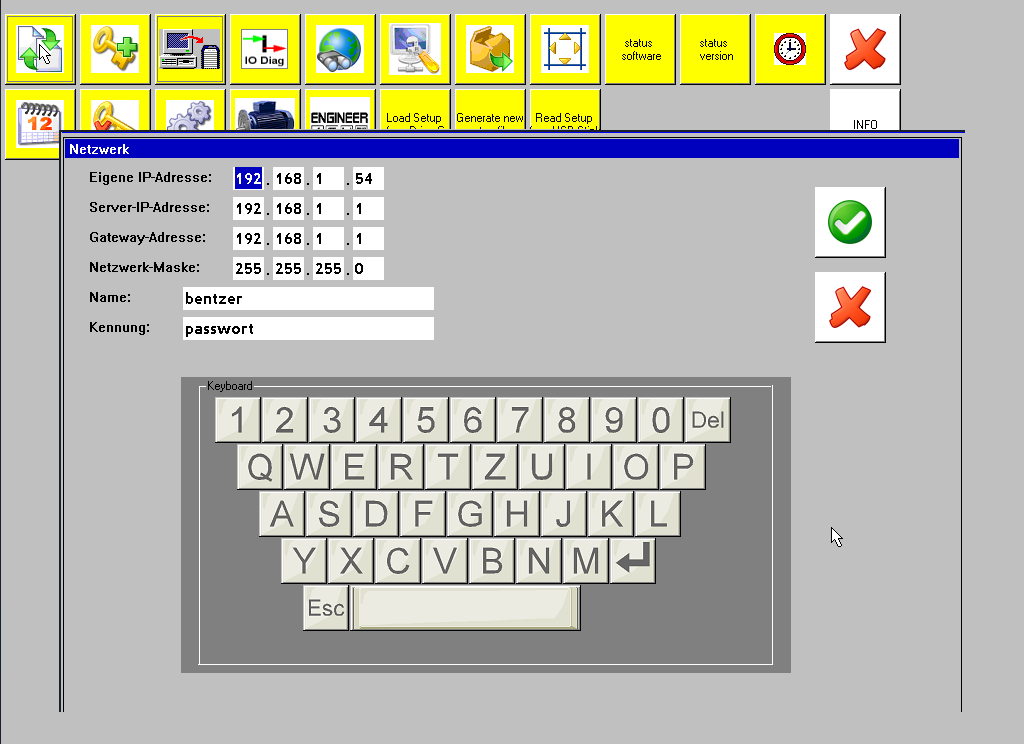

- Data management: Locally and via network

- Program memory: Up to 5,000 locally, up to 20,000 via network

🛠️ Typical Industrial Applications

- 🔌 Distribution and medium-voltage transformers

- 🔥 Dry-type power transformers

- 🧱 Cast resin transformers

- 📏 Fully insulated busbar systems

- 🔋 Converter transformers

- 🌀 Current limiting reactors (inductors)

- ⚡ Grid distribution transformers up to 20 MVA / 52 kV

✅ Summary

The RWC 5001 delivers maximum performance for large-scale winding goods with complex geometry and high wire cross-sections. Its modular design and industrial-grade control make it the ideal solution for modern energy technology.

Request a quote now

We offer individual and practical consultation.

RWC5001-4000

RWC5001-4000

|

RWC5001-4000

RWC5001-4000

|

RWC5001-4000

RWC5001-4000

|

RWC5001-4000

RWC5001-4000

|

| Technical Data | |||

| Machine Types | RWC5001-2400* | RWC5001-4000* | |

| Wire Range | mm | 250 mm² | 250 mm² |

| Traverse Width | mm | 2400 mm* | 4000 mm* |

| Clamping Length | mm | 2550 mm* | 4150 mm* |

| Max. Feed per Spindle Turn | mm | 99.99 / Spindle Revolution³ | 99.99 / Spindle Revolution³ |

| Ring Gear Drive with Fixed Gear Ratio | — | 1 | 1 |

| Stage 0 – Speed | RPM | max. 60 | max. 60 |

| Stage 0 – Torque | Nm | max. 12000 | max. 12000 |

| Spindle/Tailstock Center Height | mm | 1100* | 1100* |

| Winding Diameter | mm | 1400* | 1400* |

| Control System | Industrial PC with Single-/Dual-Core Processor** | ||

| Languages | DE, EN, AL, IT, FR, ES, CS, HU, SU, RU, PL, NL, EL, PT, ZH... | ||

| Interfaces | 2× USB2.0, 1× Ethernet, 2× RS232, 1× VGA, Foot Pedal, I/O, 2× PS/2 | ||

| OS | Robust Real-Time Operating System | ||

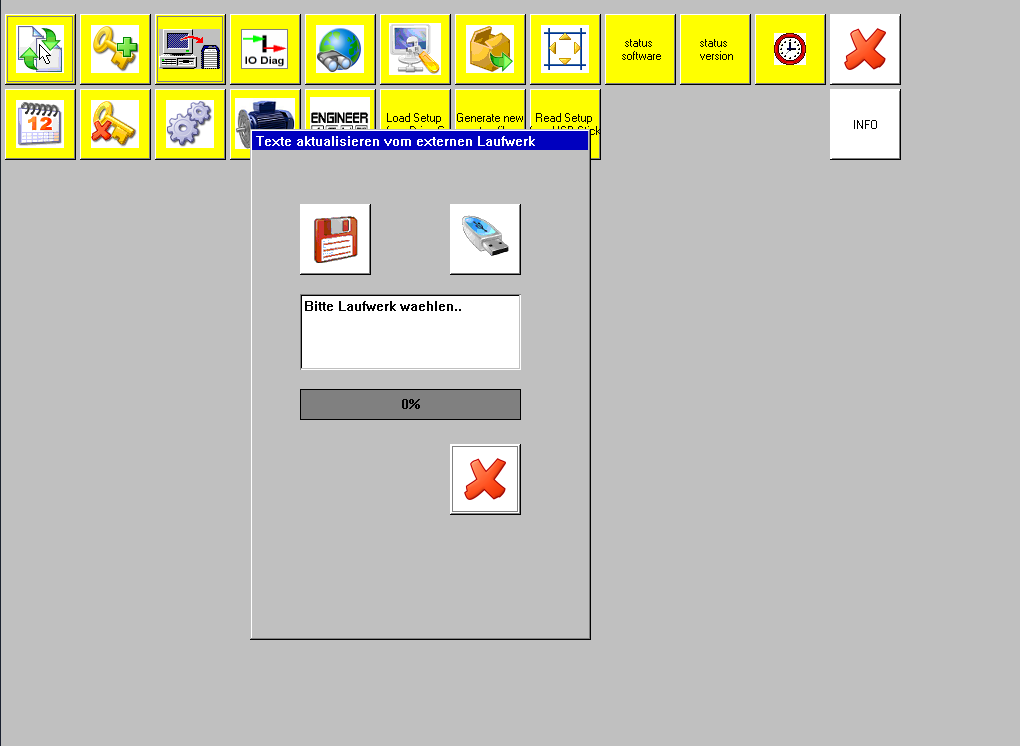

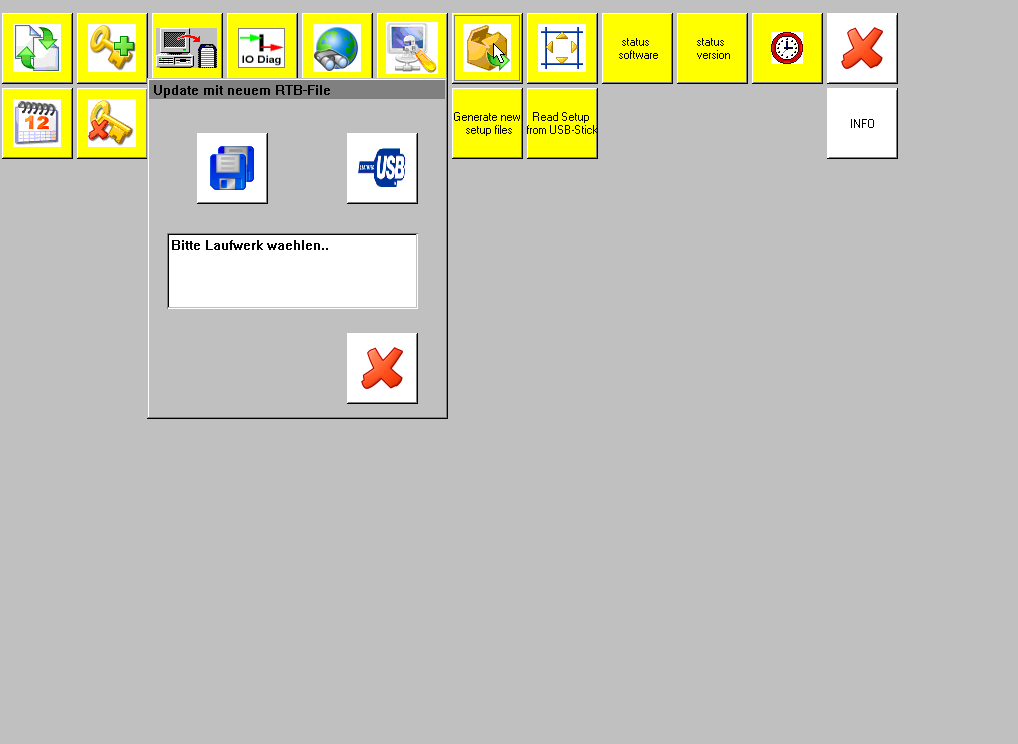

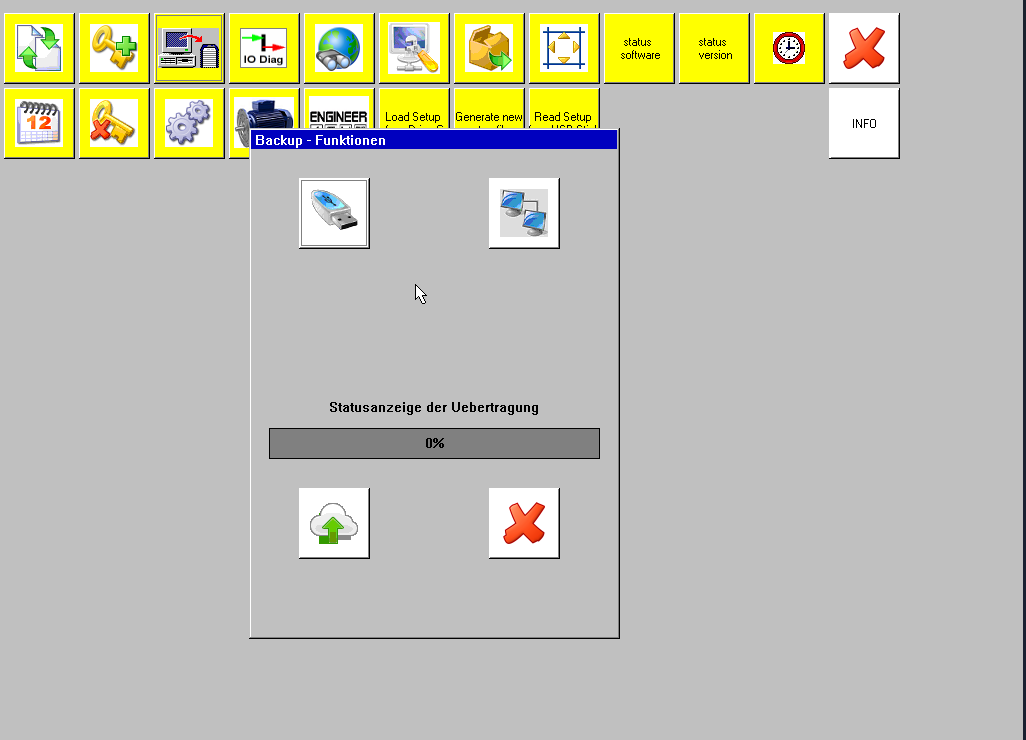

| Backup / Update | via USB and Ethernet | ||

| Printer (Optional) | USB / Parallel** | ||

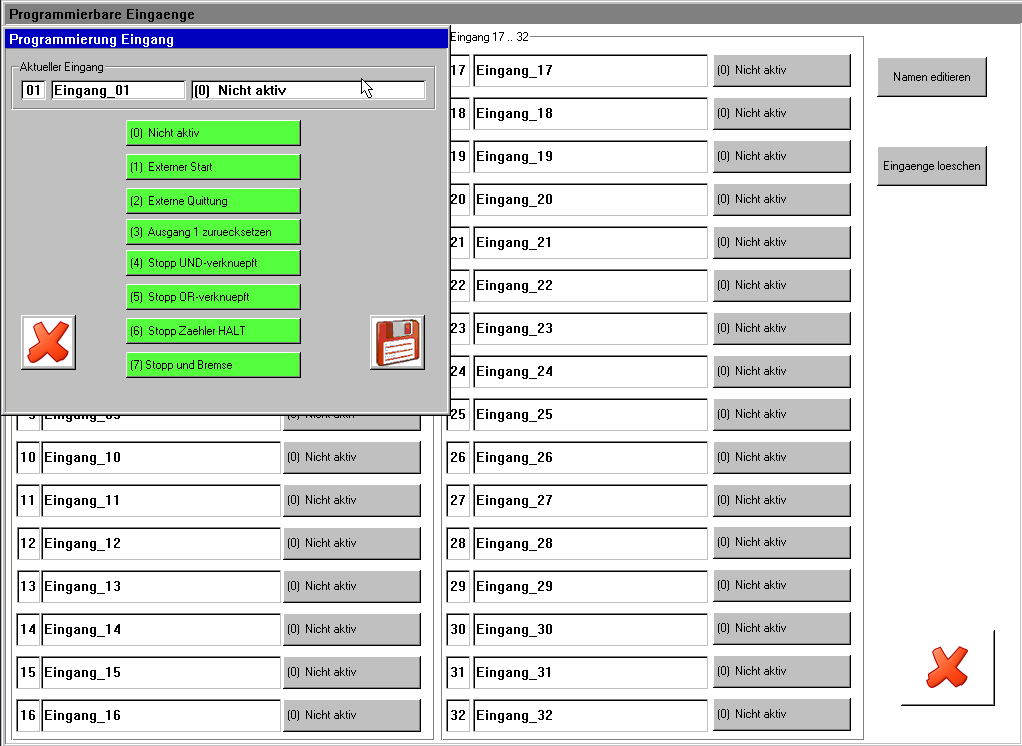

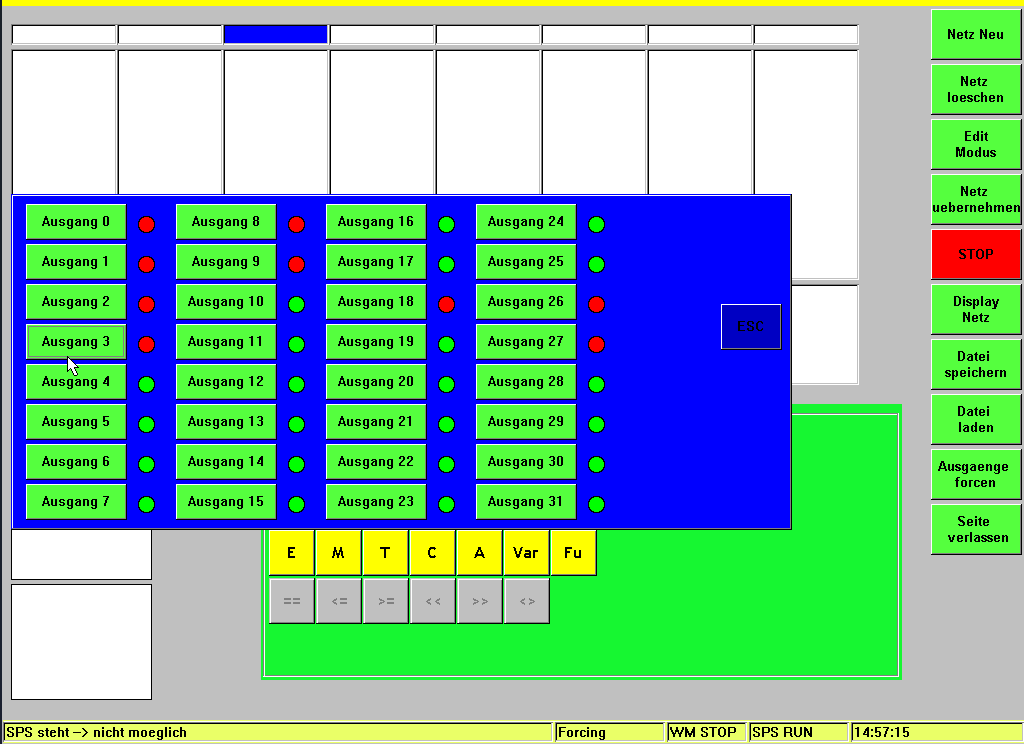

| Digital/Analog I/O (Optional) | Expandable*** | ||

| Display | 15" Standard, 15" IP65** | ||

| Keyboard | USB Wireless 2.4 GHz** | ||

| Storage | Local approx. 5,000 programs², Network approx. 20,000*** | ||

| Expansions | PLC interface integrated** | ||

| Joystick | Teach function with fixed speed for manual axis control: spindle rotation (forward/reverse) and traverse movement (left/right). | ||

| Power Rating | kVA | 61 | 61 |

| Dimensions (W×D×H) | 3730 x 2210 x 3100* | 5630 x 2210 x 3100* | |

| Power Supply | 400V – 50Hz / 100 A | ||

| Weight | approx. 2,600 kg / approx. 2,817 kg | approx. 2,884 kg / approx. 2,893 kg | |

* Specifications may vary

** Optional equipment

*** Expandable upon request

² Approx. 400 KB (500 steps incl. comments)

³ Valid for spindle speed × feed < 3600/min

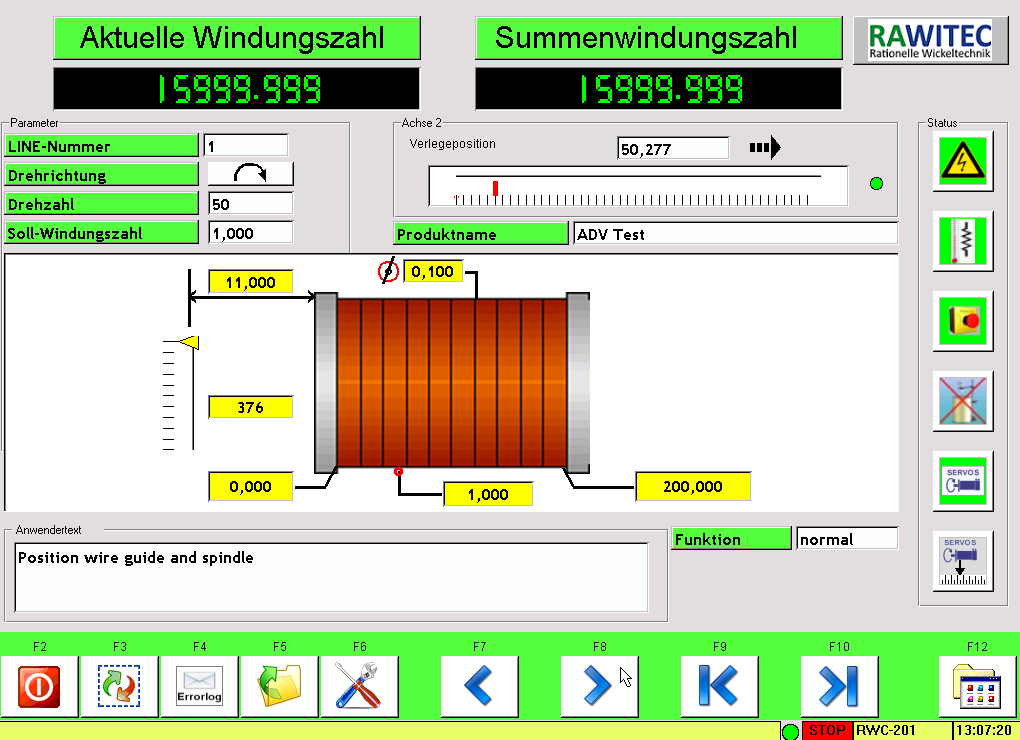

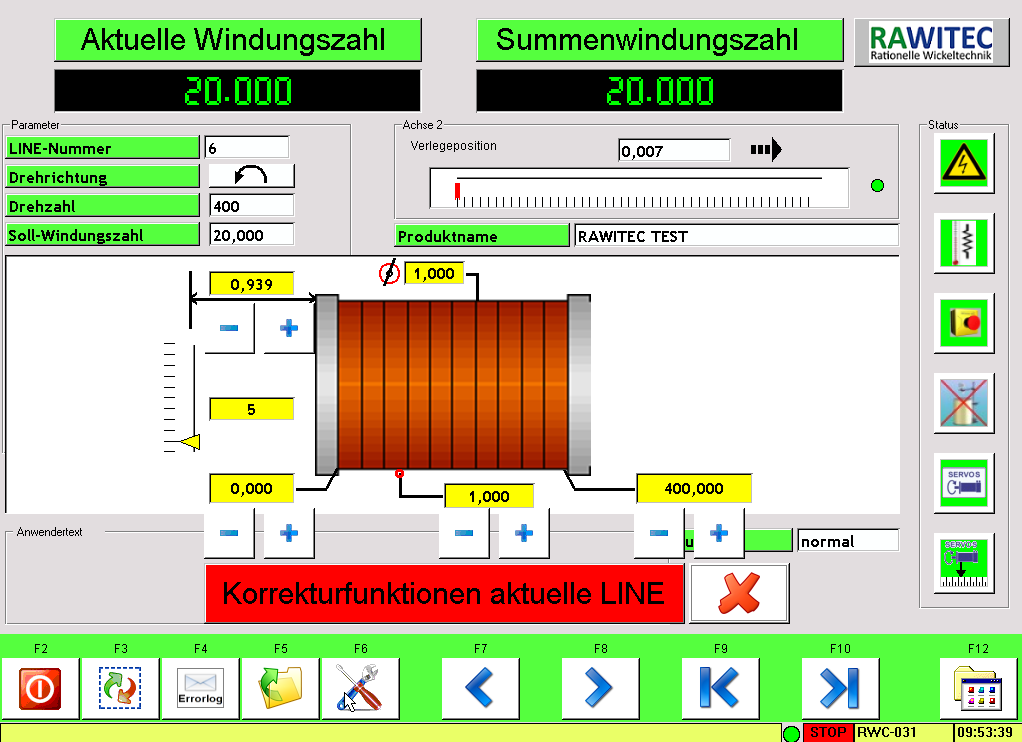

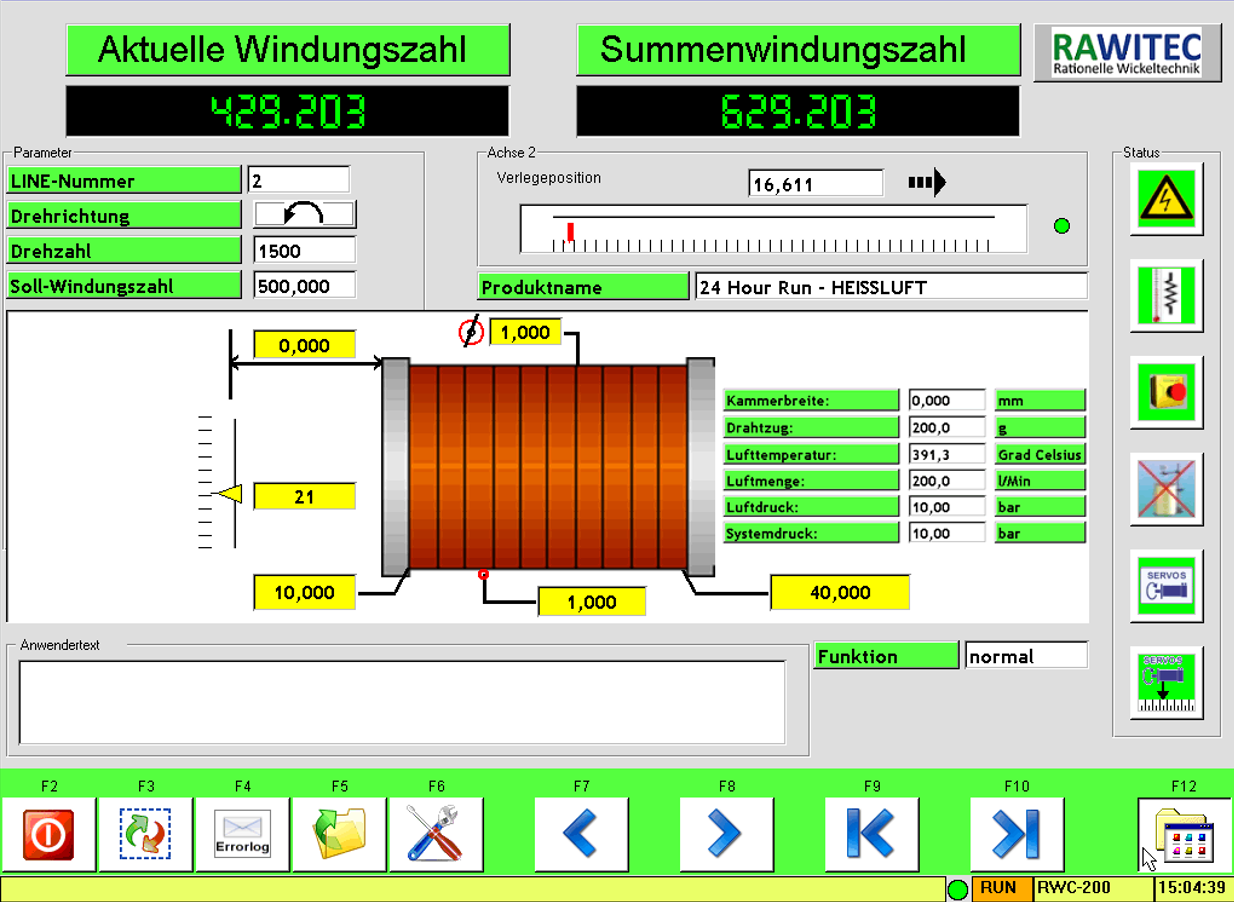

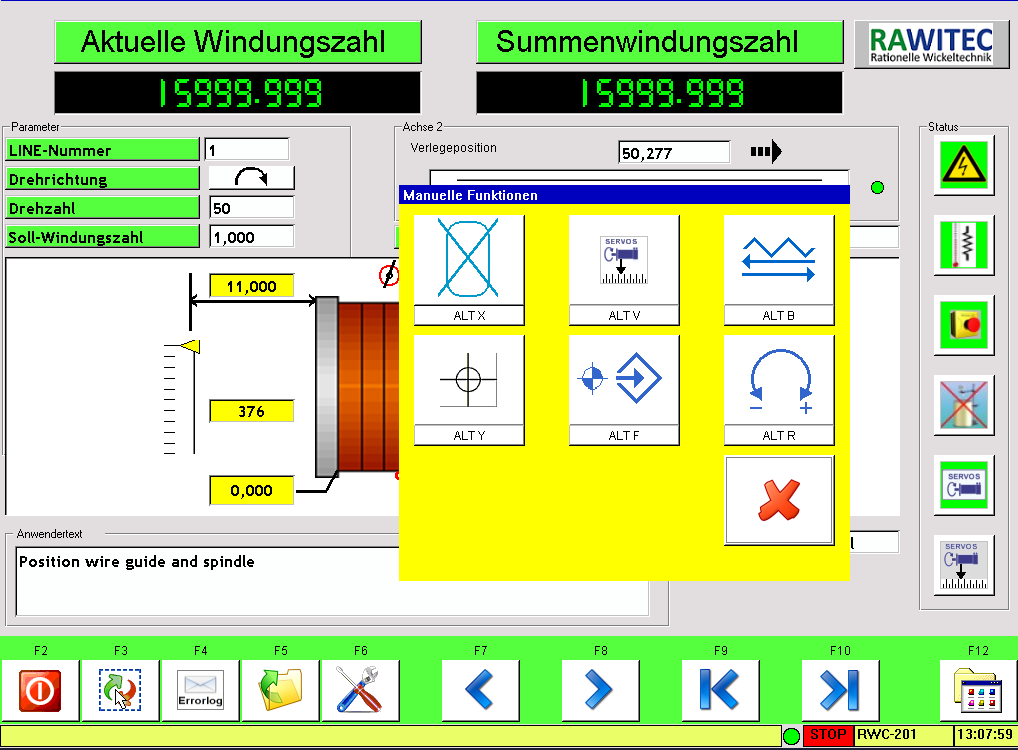

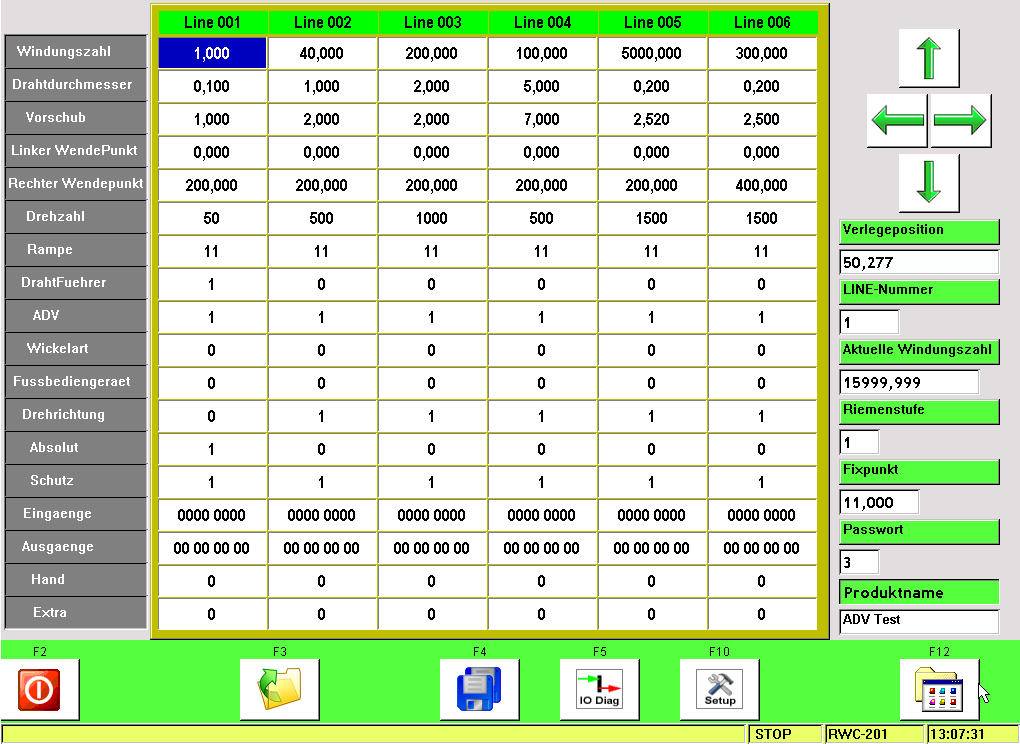

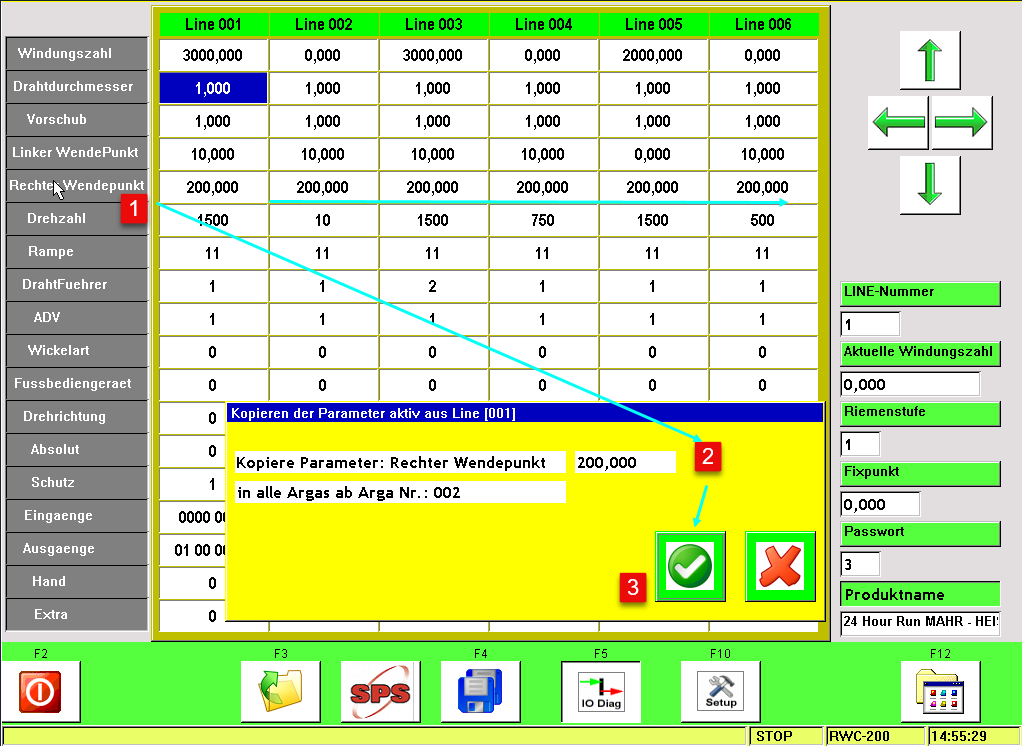

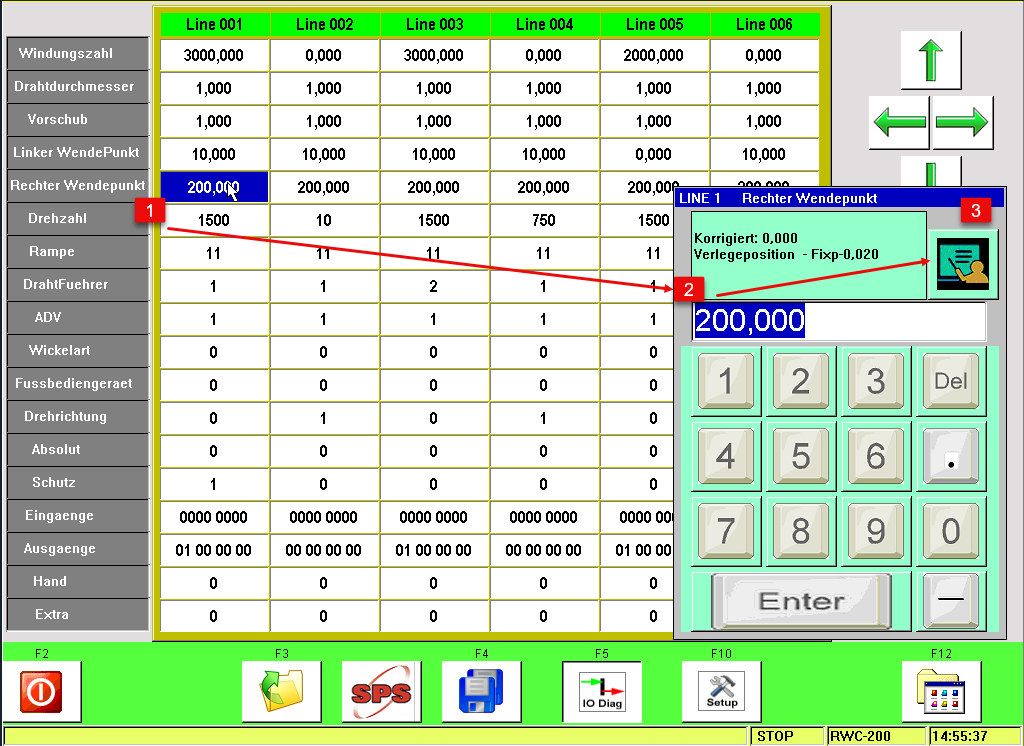

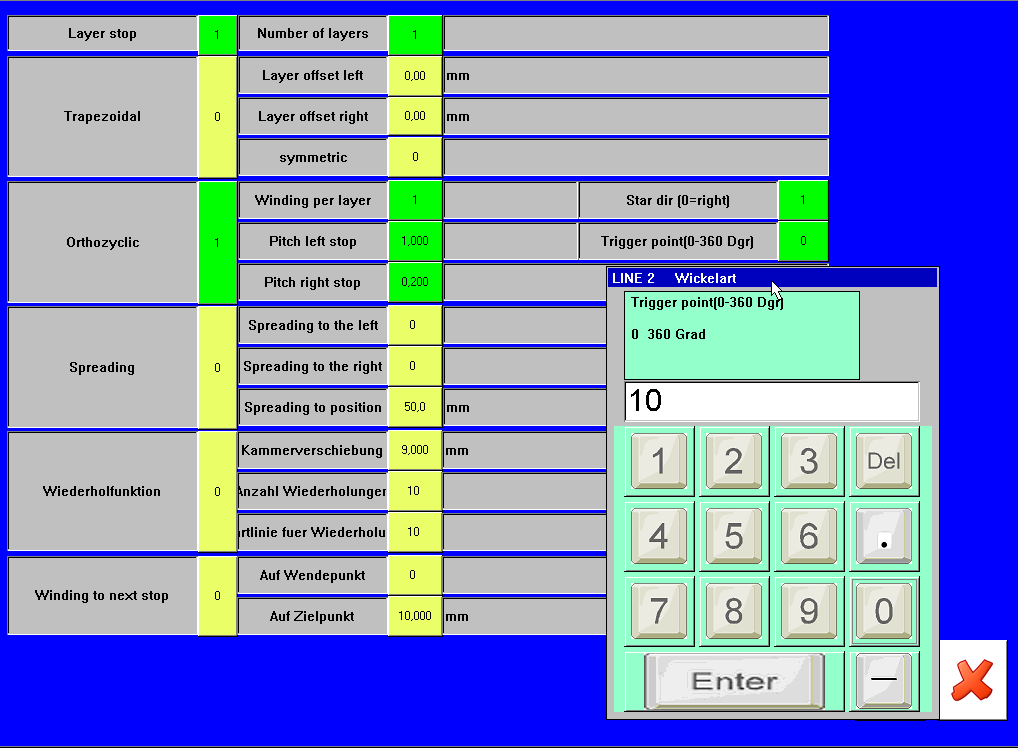

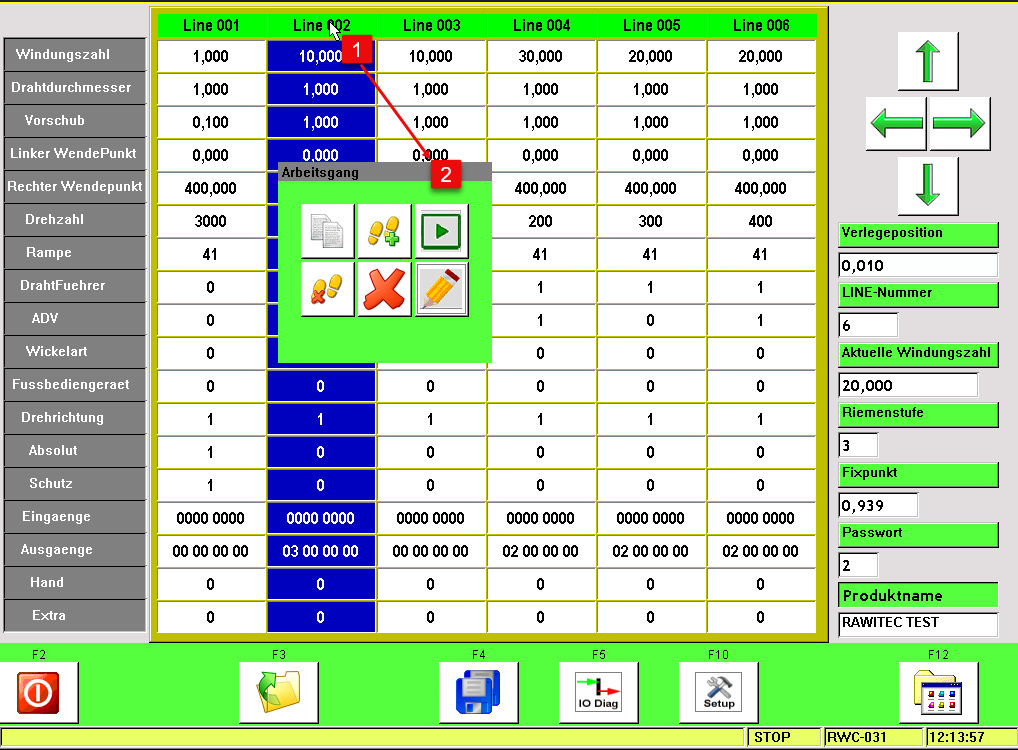

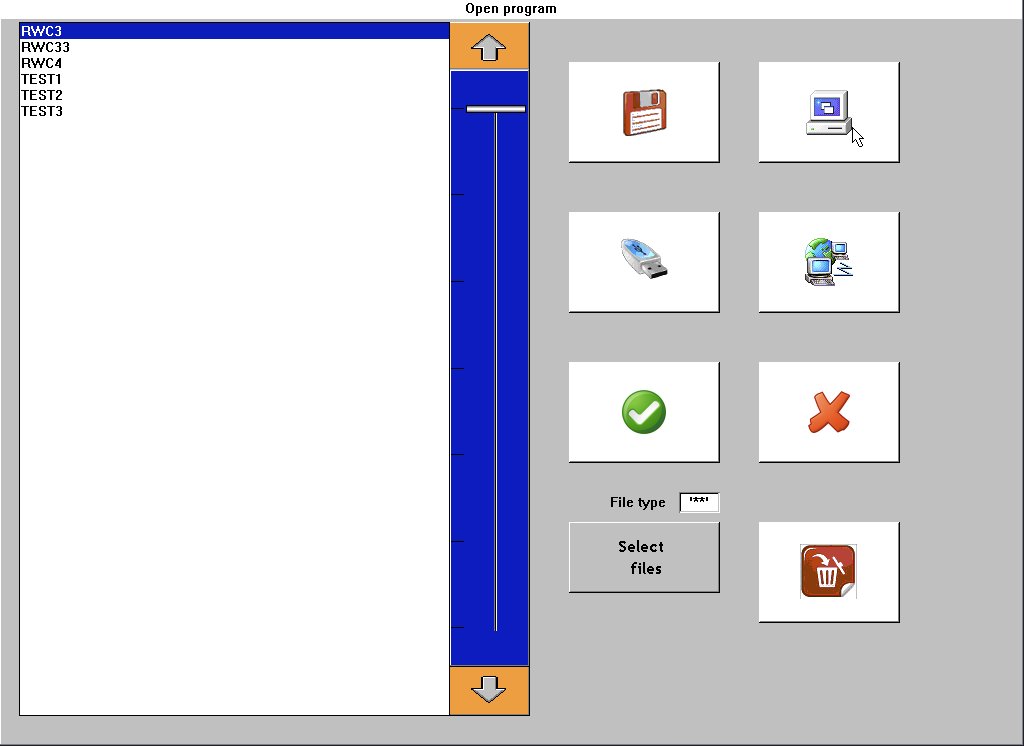

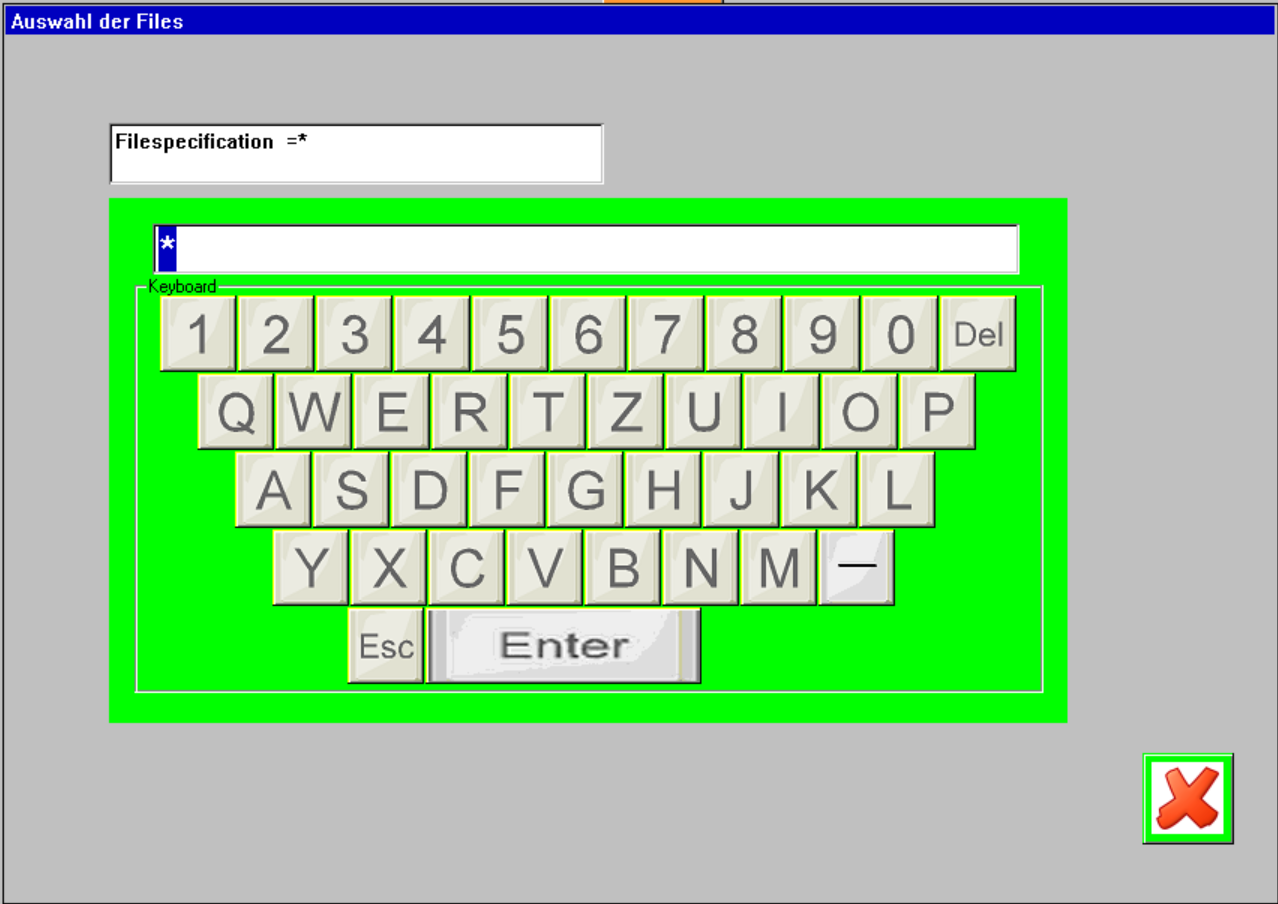

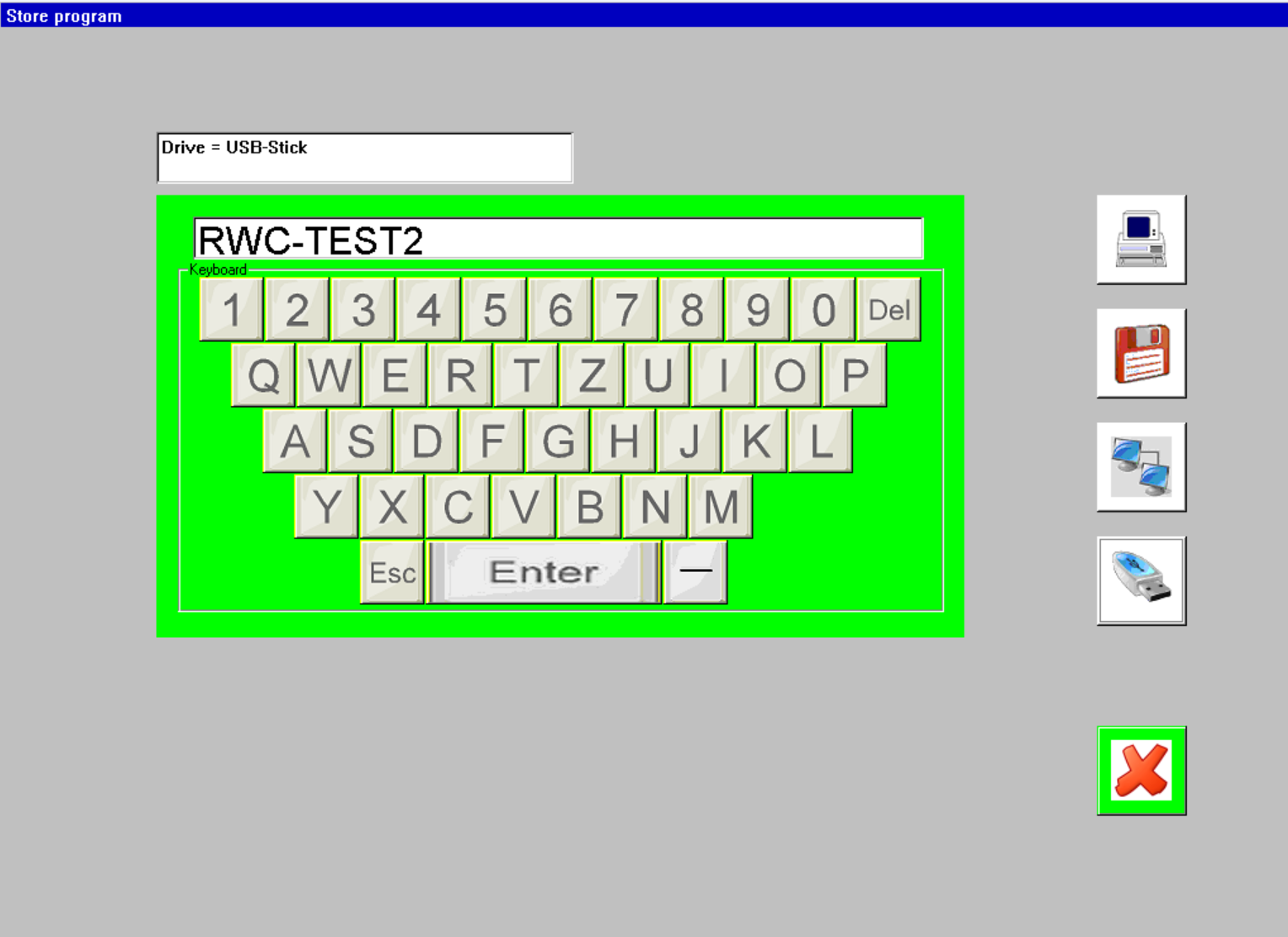

Intuitive Touch Software for Winding Machines – Powerful & Versatile

The user interface was specially developed for intuitive and efficient touch operation on winding machines.

In addition to essential functions such as Open, Save, Copy, Delete, Edit, and Print winding programs, the software offers numerous advanced features:

- Integrated language switch for international use

- Extensive configuration options

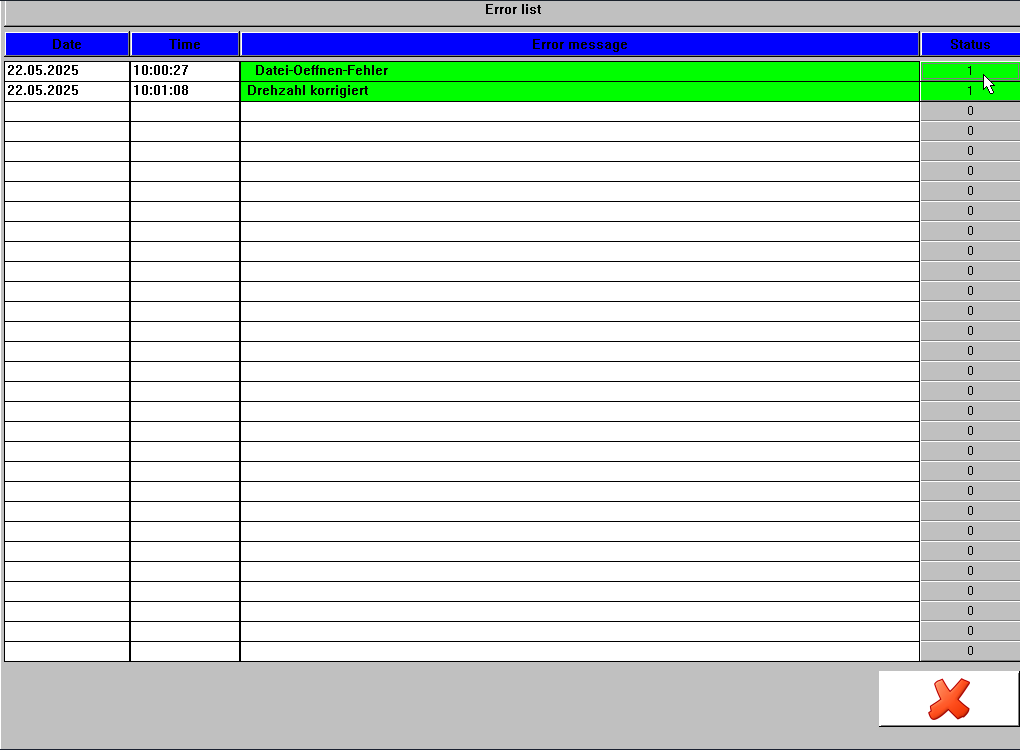

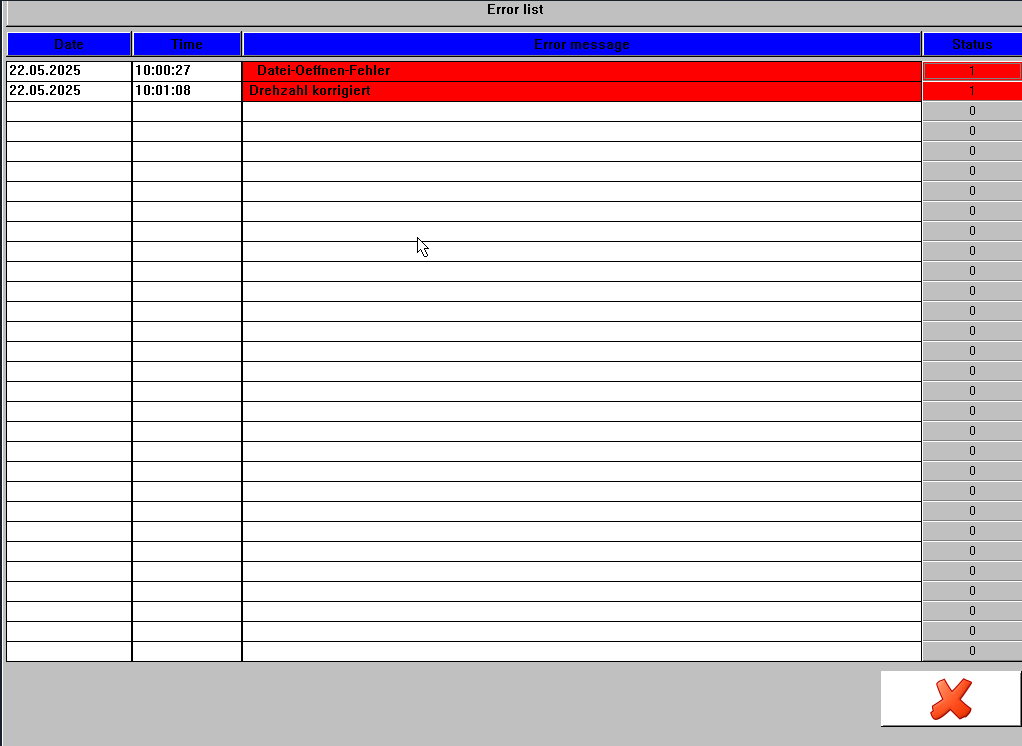

- Service-relevant diagnostic tools

- Tools for system optimization and machine customization

Thanks to its clearly structured interface, the software supports both machine operators in daily production and technical staff during machine configuration and customization.

🔧 Dynamic Performance Curves – RWC 5001

The diagram below illustrates the relationship between winding radius and the resulting wire tension force under different operating conditions of the RWC 5001 winding machine.

As the winding radius increases – i.e., as the spool diameter grows – the force on the winding axis decreases. The physical principle is straightforward:

Power = Torque × Speed

Since the machine power remains constant, the torque decreases with increasing speed – which also reduces the possible wire tension force.

📈 Diagram Interpretation

- The lines represent the wire tension [N] depending on the winding radius [mm] for different RWC5001 configurations.

- The left Y-axis is logarithmic to visualize both low and high tension values clearly.

- The right Y-axis displays typical wire diameters [mm] as a guide for wire selection.

- The RWC5001 offers high torque – ideal for thick wires and large coil diameters.

🧩 Practical Use

This chart supports decision-making when selecting the appropriate drive configuration:

- Adaptation to wire gauge (e.g. 0.4 mm to 20 mm)

- Consideration of the required tension range

- Dependent on the desired winding speed

- Optimized for the respective coil diameter

The RWC 5001 can thus be precisely tuned for various applications in transformer and power technology.

🔎 Note: Actual wire tension also depends on the wire material, brake configuration, and friction. All values shown are approximate based on the gear configuration.

RWC 5001 – Robust winding technology for thick wires and large coils

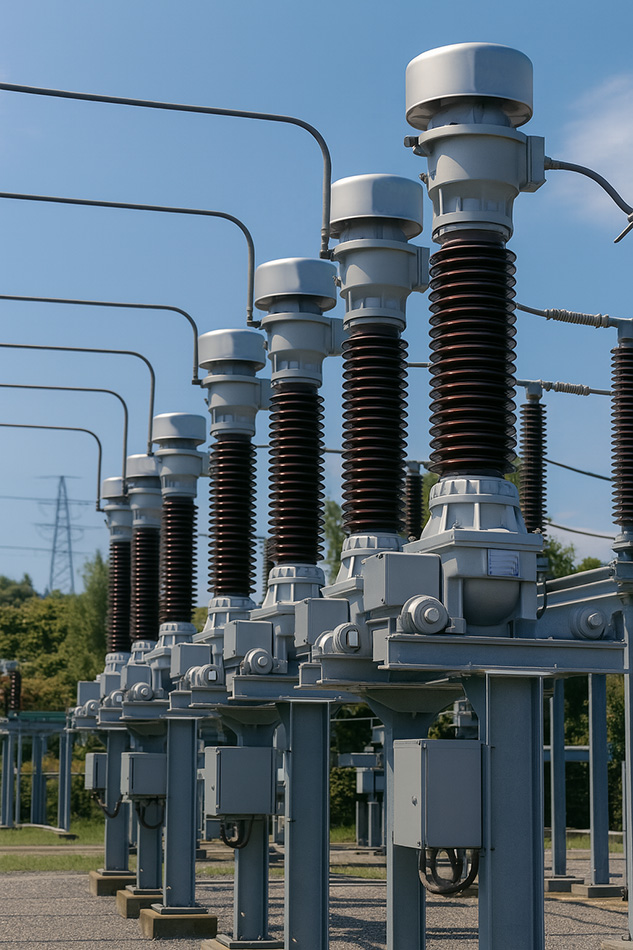

🏗️ Typical industrial applications:

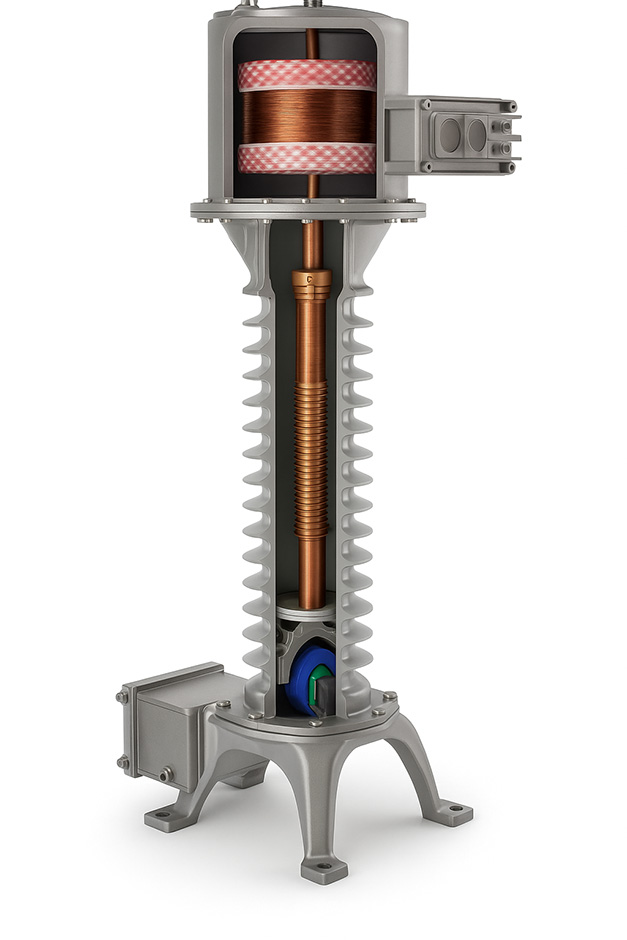

🔧 High-performance winding machine: The RWC 5001 is ideal for large-volume coils with high cross-sections – designed for industrial applications up to high-current ranges.

📐 Flexible geometry: Linear winding on round and rectangular coil bodies – optionally with integrated cooling channels.

🧩 Modular and scalable: Perfect for custom-built single pieces as well as for high-performance series production.

- 🔋 Cast resin and dry-type power transformers

- 🏭 Distribution and medium-voltage transformers

- 📏 Measuring transformers, current transformers, and choke coils

- 📦 Fully insulated busbar systems

- 🔋 Converter transformers and reactance coils

- ⚡ Grid distribution transformers up to 20 MVA / 52 kV

✅ Your benefits at a glance:

- 🎯 Flexible parameterization and easy adaptation to various winding tasks

- 🧵 Processing of thick wires on various coil geometries

- 📈 Maximum repeatability and process reliability – even with heavy coils up to 3.5 tons

- 🖥️ Intuitive control via modern touch panel

- 🔄 Expandable with options such as tailstock, automatic wire guide, and PLC interfaces

🏗️ Ideal for large-scale industrial projects: The RWC 5001 stands for reliable high-performance winding in energy and transformer technology.