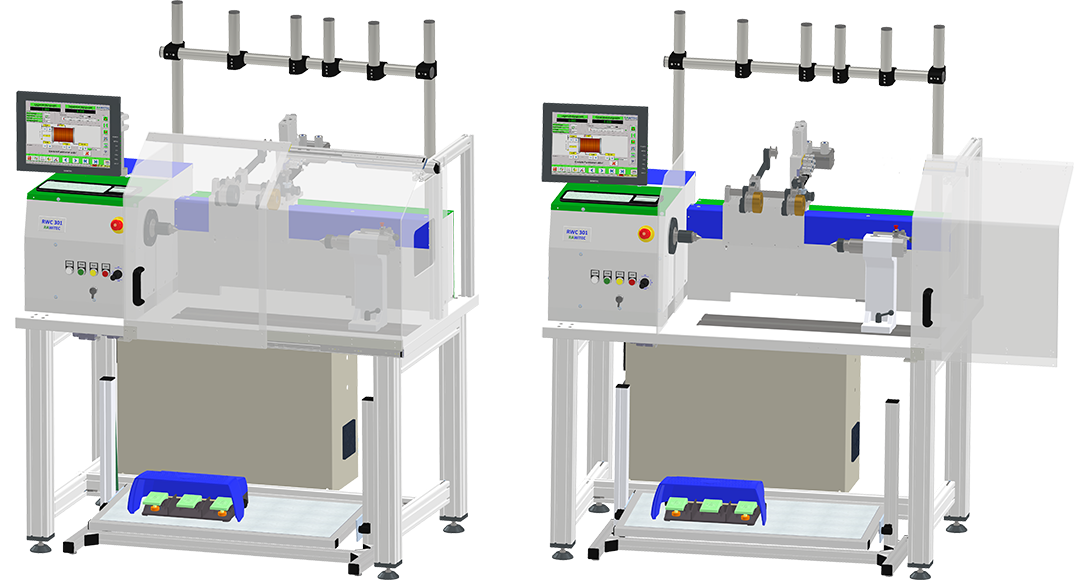

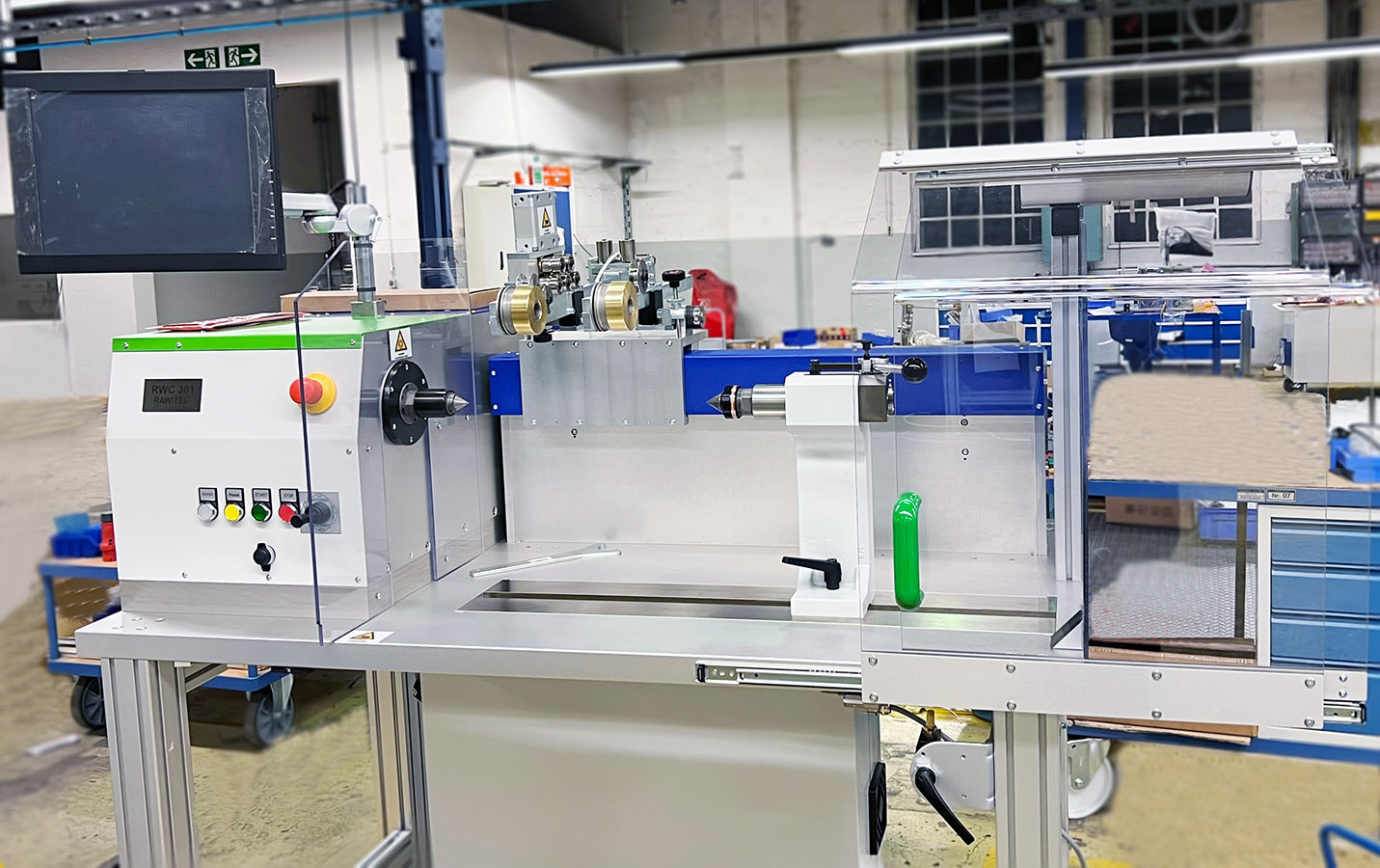

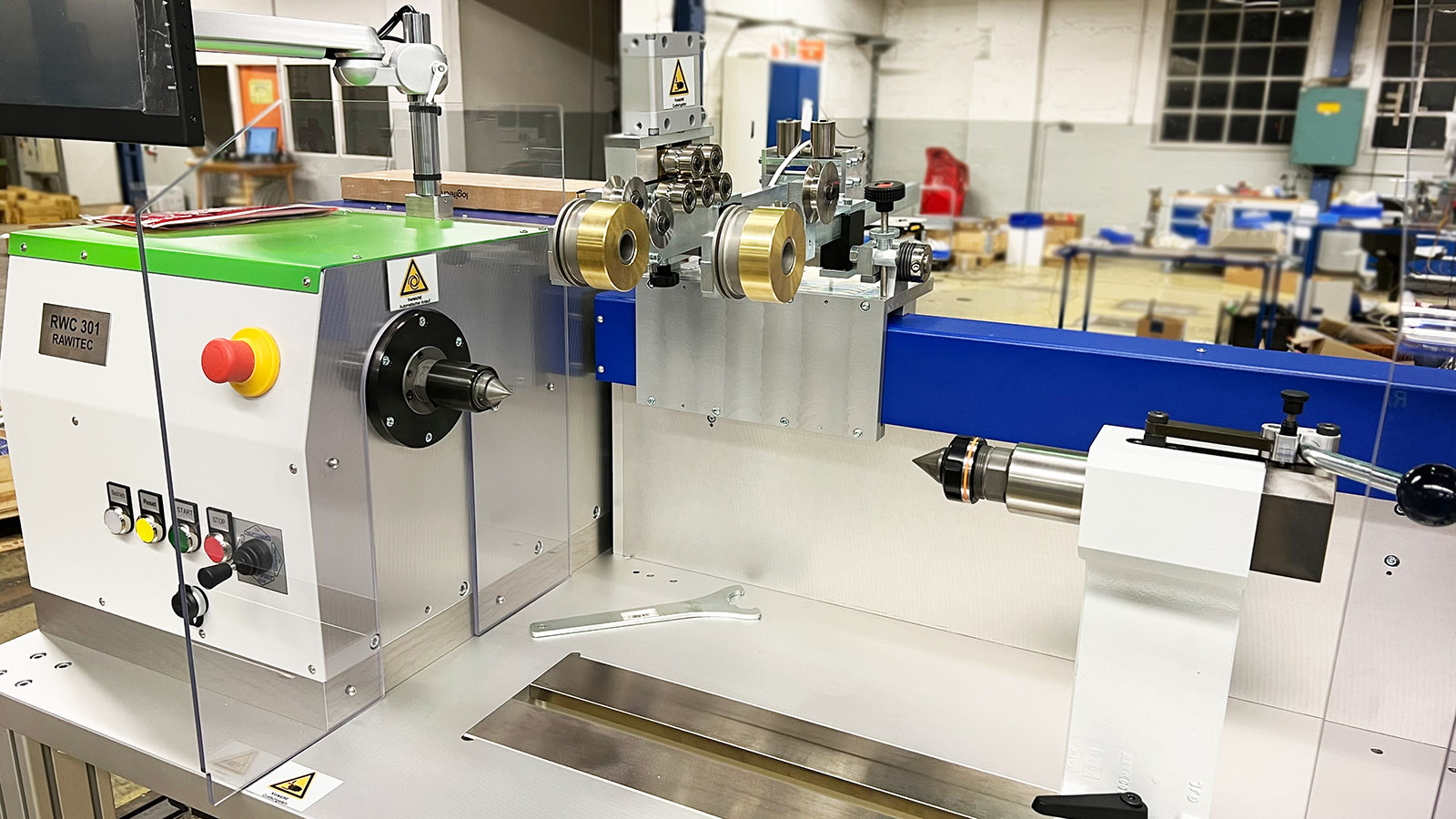

RWC 301-R – Versatile Winding Technology for the Highest Demands

The RWC 301-R is the ideal solution for precise and efficient winding of medium to large coils – highly flexible for a wide range of wire gauges, robust round and flat wires, and diverse production requirements.

🌐 Versatility & Flexibility

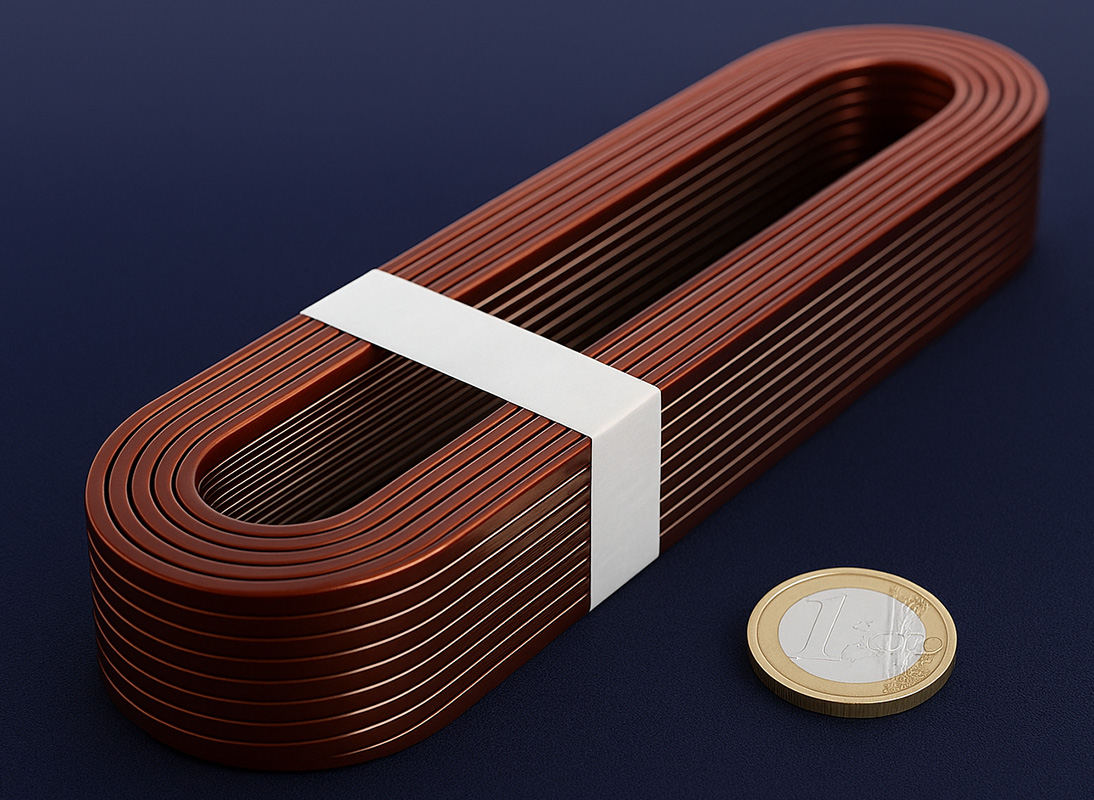

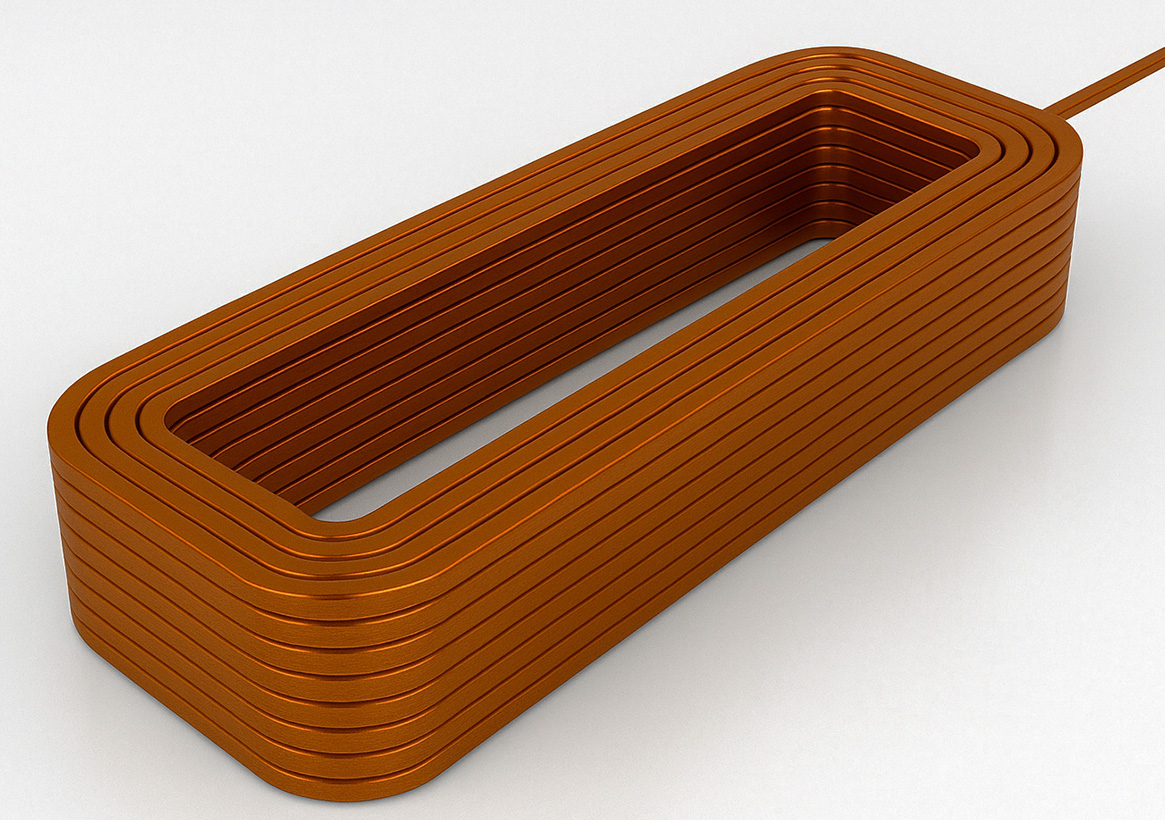

- Wide range of applications: Suitable for fine to very thick wires and flat copper

- Variable traverse units: Available with working widths of 500 mm, 750 mm, or 1000 mm

- Customizable center height: 180 mm, 250 mm, or 300 mm – higher center heights on request

- Flexible installation: Supplied as standard with a table frame and aluminum plate

⚡ Advanced Drive Technology

- Powerful AC synchronous servo motors: For precise and dynamic movement sequences

- Air-cooled high-performance servo controllers: For maximum process reliability, even in complex winding applications

🖥️ Intelligent Control & User Comfort

- Intuitive operating interface: Directly at the machine

- External program creation: Using the RAWITEC winding program editor (Windows), Microsoft Excel, or WiDaMa system

- Central program management: Via file server

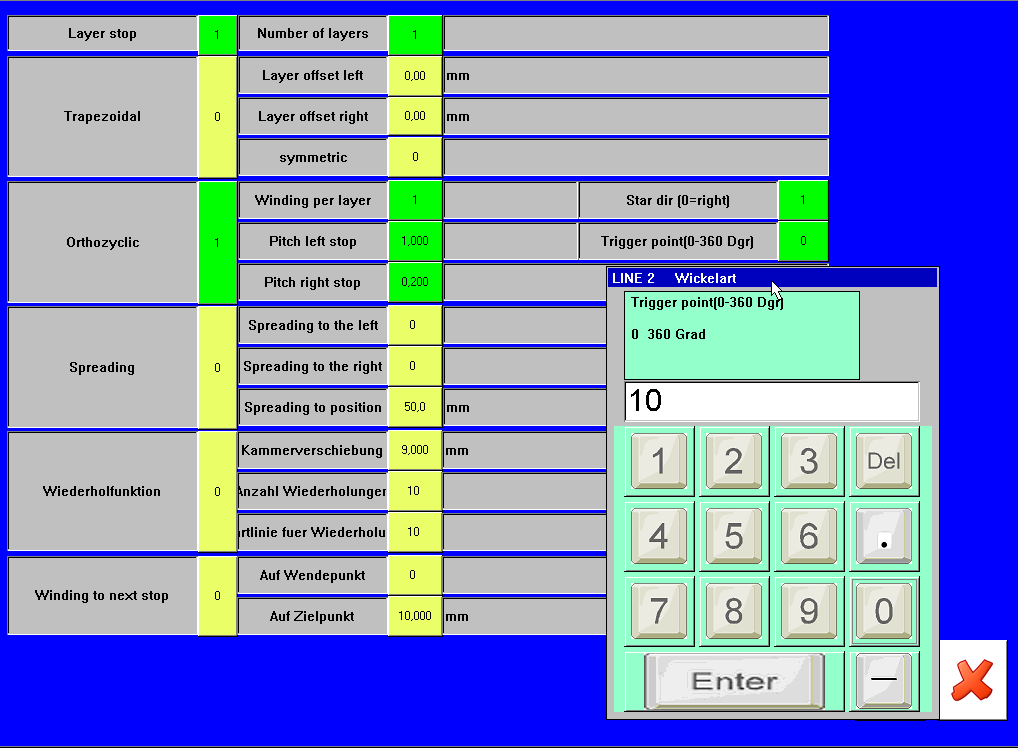

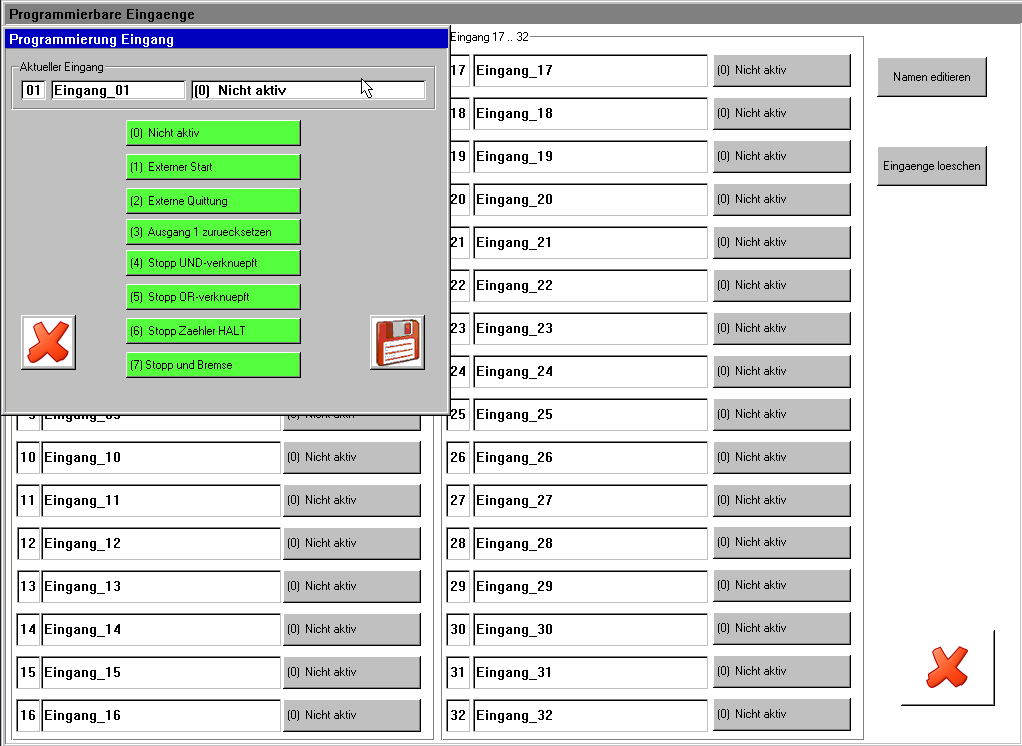

- Fully programmable winding parameters: For maximum flexibility

- Freely definable winding types: For a wide variety of applications

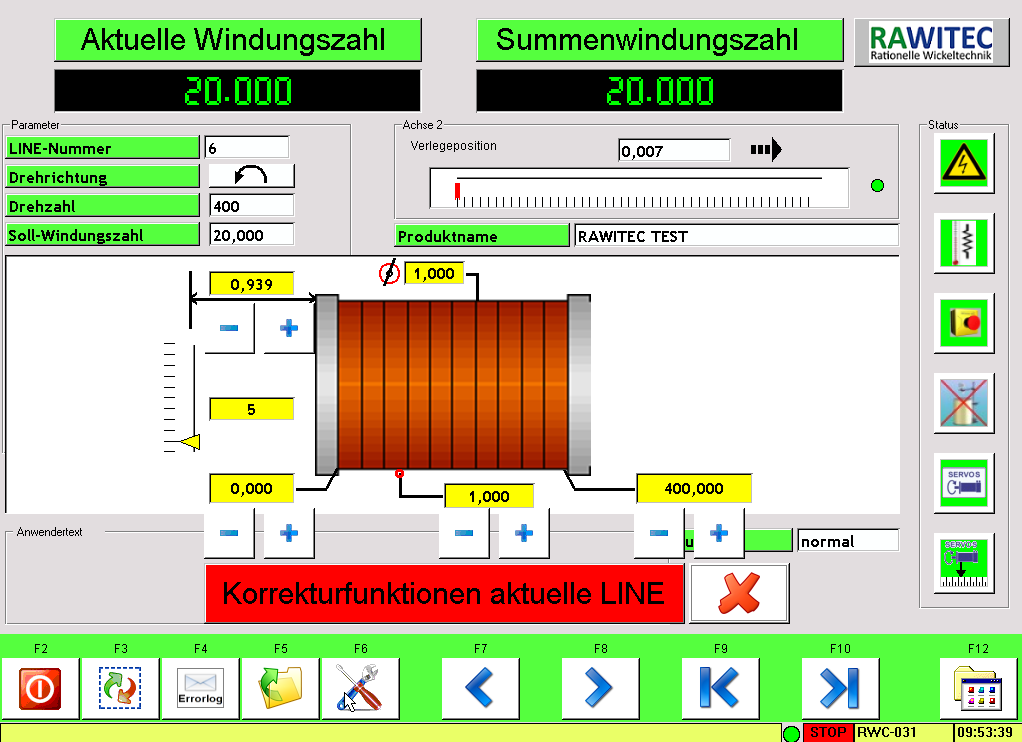

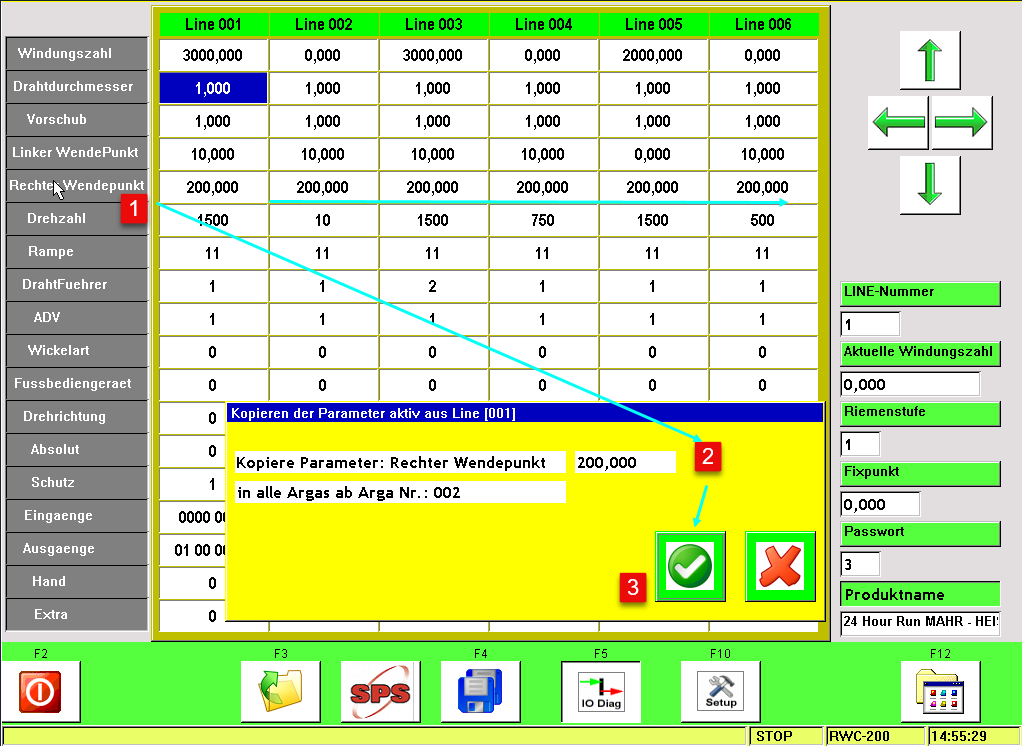

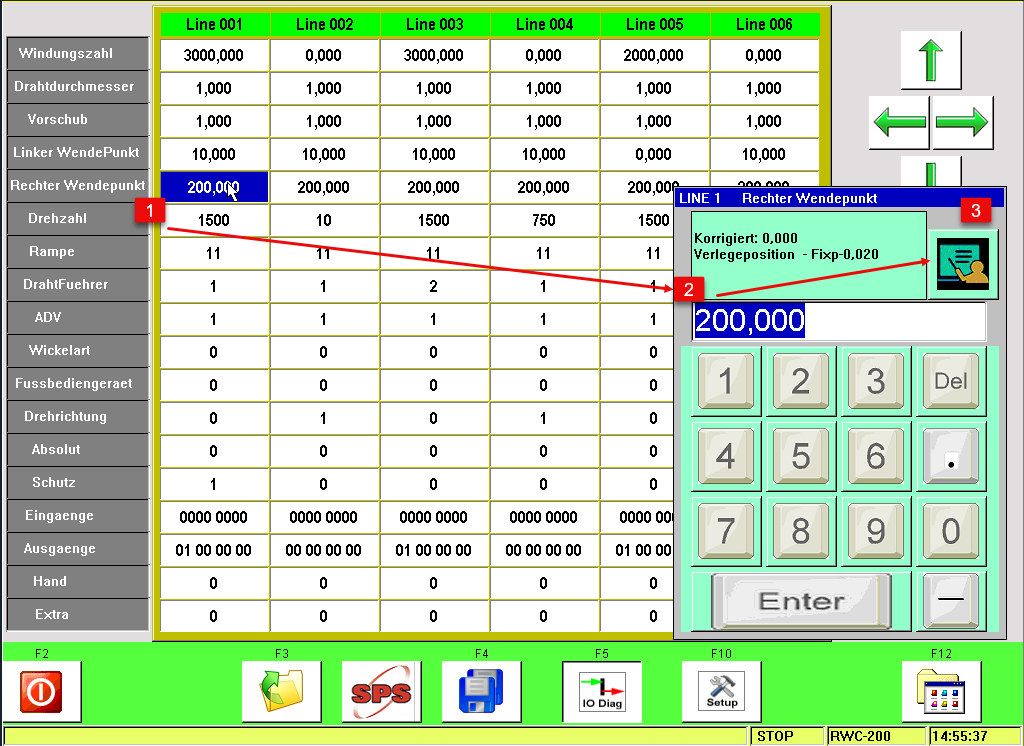

- Quick corrections: Optimization possible at any time during operation

🛠️ Efficient Mechanics & Data Handling

- Easy adjustment of torque and speed: By changing belts and gears

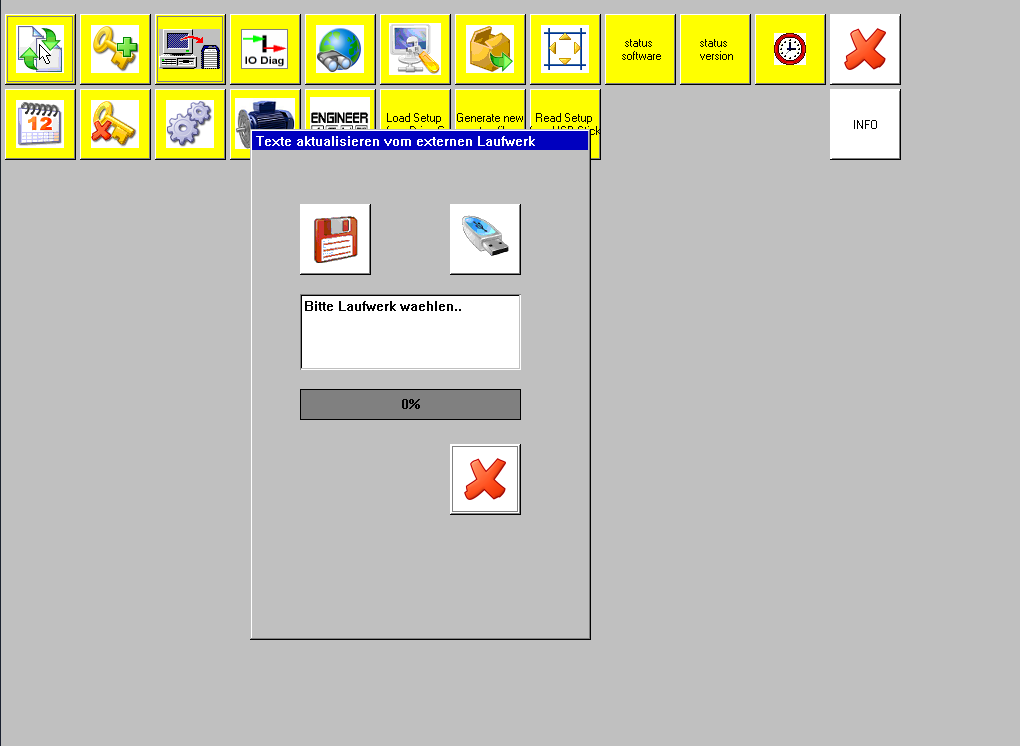

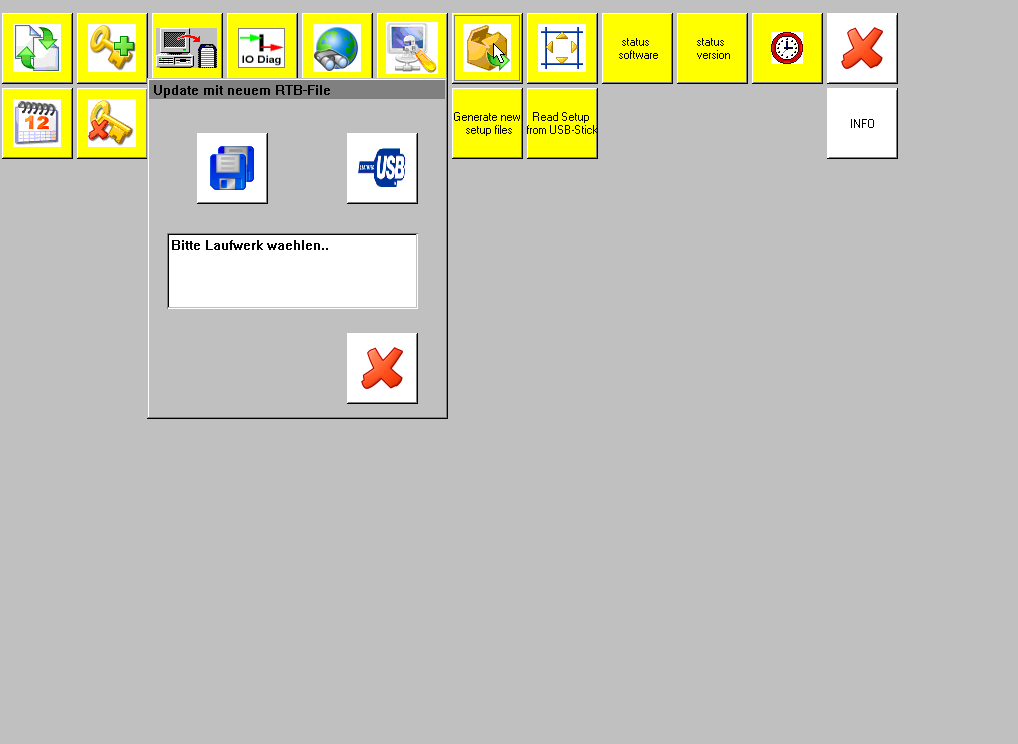

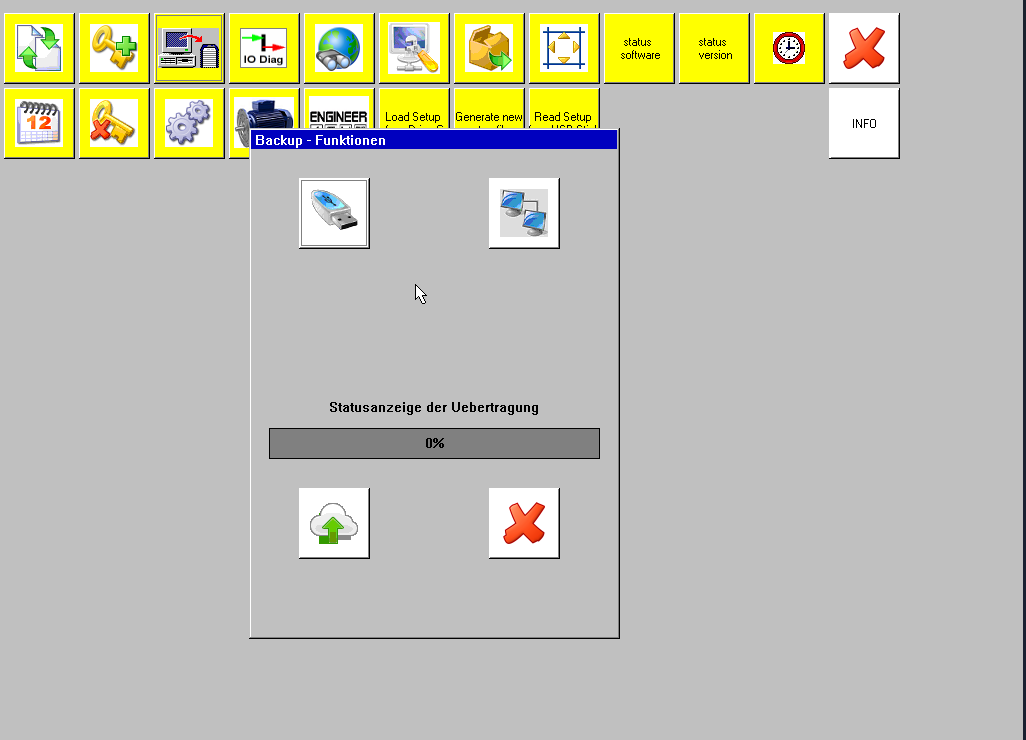

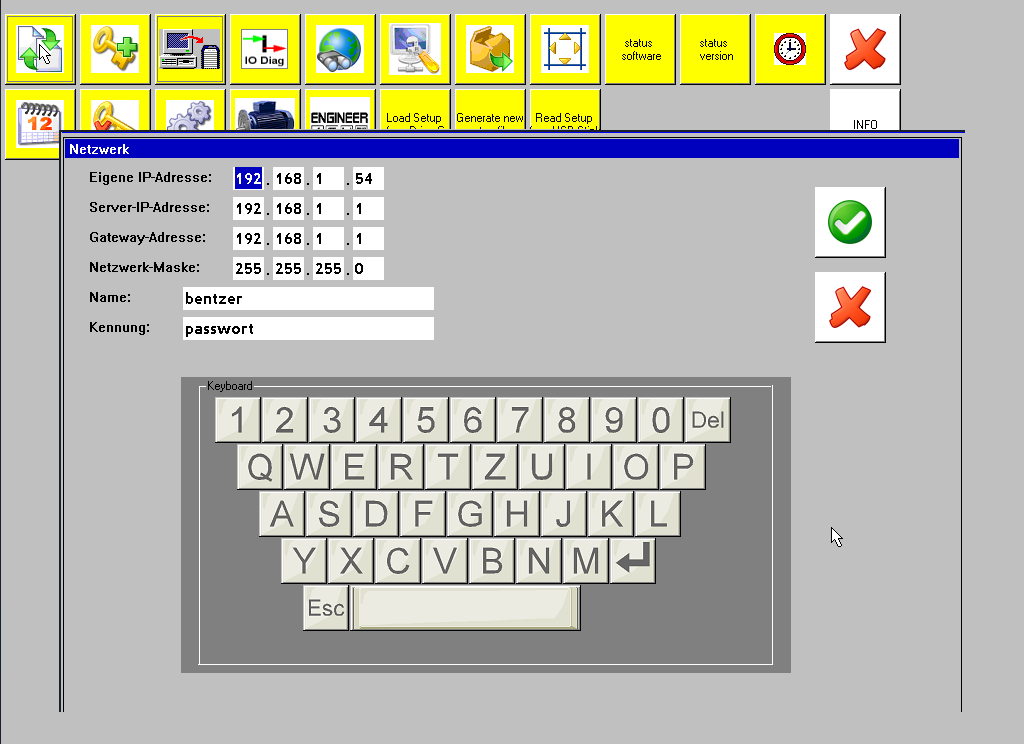

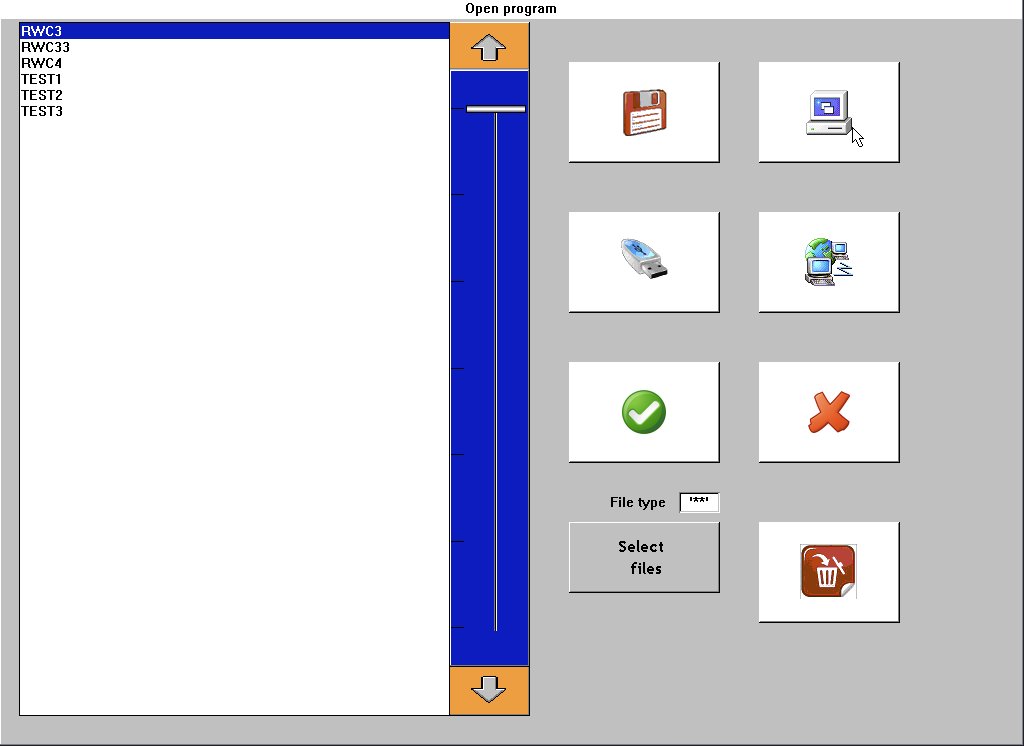

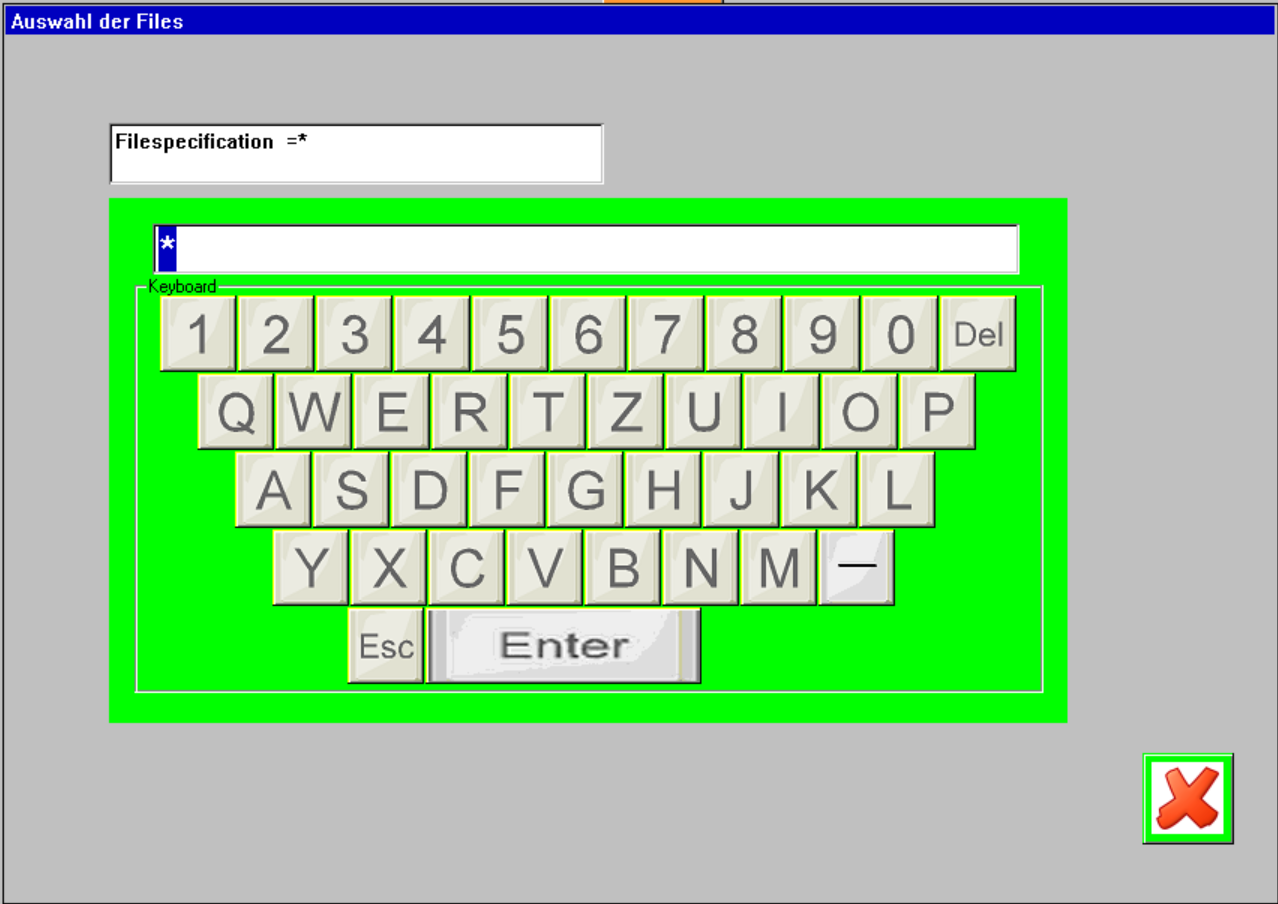

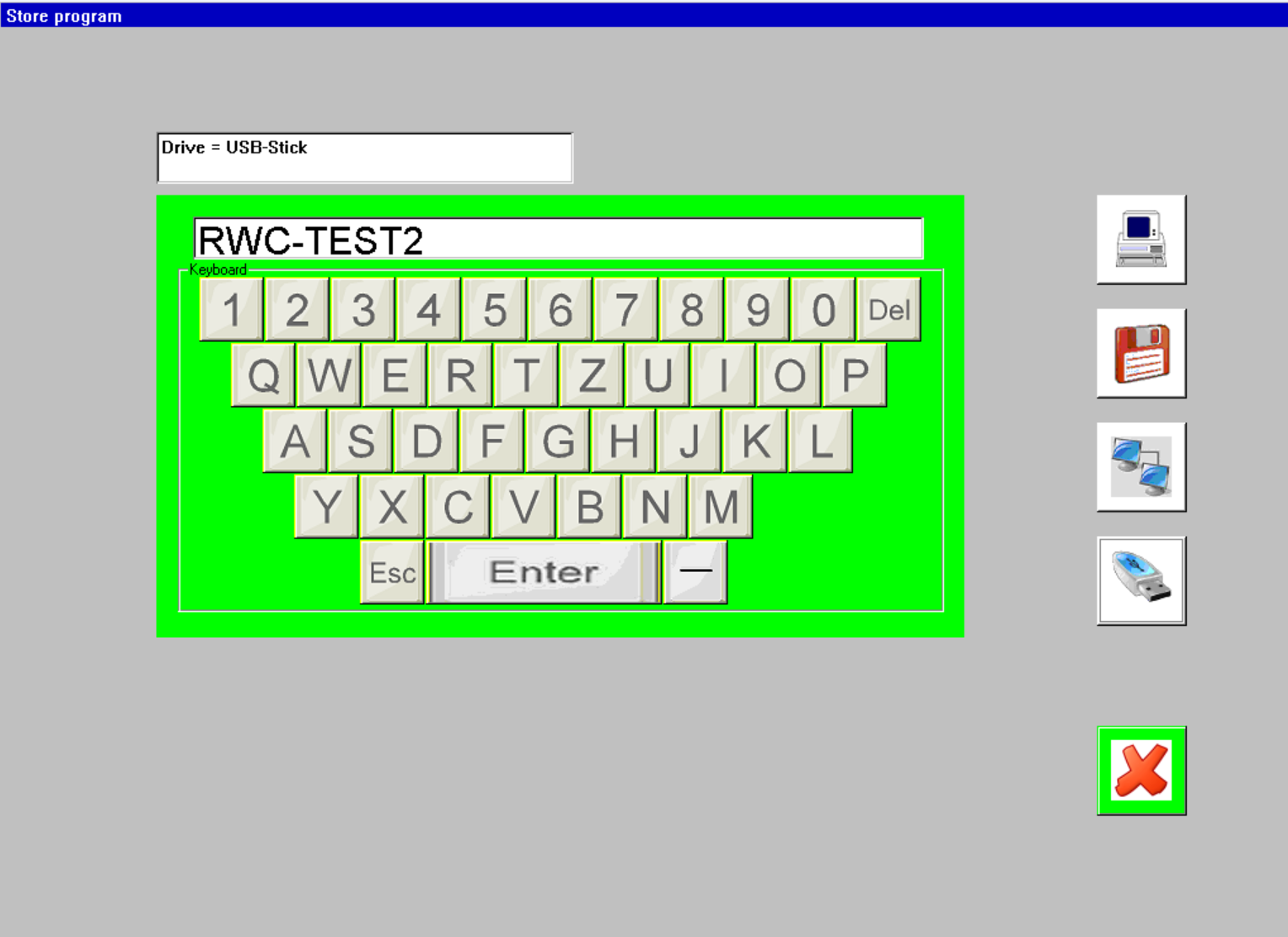

- Program transfer via USB or LAN

- Integrated flash memory: For secure storage of all programs and machine parameters

✅ Conclusion

The RWC 301-R stands for precision, flexibility, and efficiency – ensuring maximum productivity and consistent winding quality in your production.

Request a quote now

We will be happy to advise you individually for your application.

RWC301-R 500

RWC301-R 500

|

RWC301-500

RWC301-500

|

| Technical Data | ||||

| Machine Types | RWC301-S* | RWC301-V1* | RWC301-V2* | |

| Wire range | mm | 0.01 - 5.0 | 0.01 - 6.0 | 0.01 - 8.0 |

| Winding width | mm | 500/750 mm * | 500/750 mm * | 500/750/1000 mm * |

| Clamping length | mm | 650/1150 mm * | 650 / 1150 mm * | 650 / 900 / 1150 mm * |

| Max. traverse feed | mm | 99.99 / spindle revolution ³ | 99.99 / spindle revolution ³ | 99.99 / spindle revolution ³ |

| Belt level | — | 0 - 3 | 0 - 2 | 0 - 2 |

| Belt level 0 – Speed | rpm | max. 750 | max. 750 | max. 750 |

| Belt level 0 – Torque | Nm | max. 50.4 | max. 64.0 | max. 80.0 |

| Belt level 1 – Speed | rpm | max. 1,500 | max. 1,500 | max. 1,500 |

| Belt level 1 – Torque | Nm | max. 25.2 | max. 32.0 | max. 40 |

| Belt level 2 – Speed | rpm | max. 3,000 | max. 3,000 | max. 3,000 |

| Belt level 2 – Torque | Nm | max. 12.6 | max. 16.0 | max. 20.00 |

| Belt level 3 – Speed | rpm | max. 6,000 | ||

| Belt level 3 – Torque | Nm | max. 6.03 | ||

| Spindle-/Tailstock center height | mm | 180* /250/300 **** | 180* /250/300 **** | 180* /250/300 **** |

| Winding diameter | mm | 350 / 500 /600 * | 350 / 500 /600 * | 350 / 500 /600 * |

| Control | Industrial PC with single-/dual-core processor ** | |||

| Languages | DE, EN, AL, IT, FR, ES, CS, HU, SU, RU, PL, NL, EL, PT, ZH... | |||

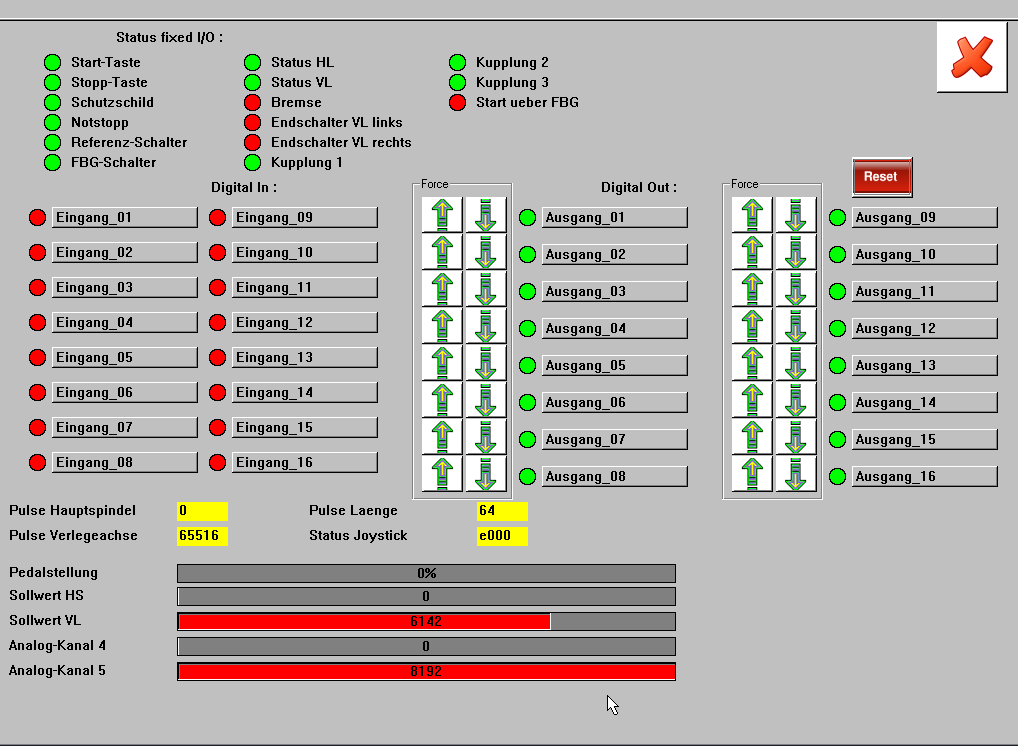

| Connections | 2× USB2.0, 1× Ethernet, 2× RS232, 1× VGA, foot pedal, I/O, 2× PS/2 | |||

| OS | Robust real-time operating system | |||

| Data backup / Update | via USB and Ethernet | |||

| Printer (optional) | USB / Parallel ** | |||

| Digital/Analog I/O (optional) | Expandable *** | |||

| Display | 15" Standard, 12.1" / 15" IP65 ** | |||

| Keyboard | USB Wireless 2.4 GHz ** | |||

| Storage | Local approx. 5,000 programs², network approx. 20,000 *** | |||

| Extensions | PLC interface integrated ** | |||

| Joystick | Teach function for manual axis control: Right/left rotation of the winding axis (CW/CCW), traverse movement left and right | |||

| Connection values | kVA | 5.1 | 5.8 | 7.2 |

| Dimensions (W×L×H) | 850 × 1650 × 750 | 850 × 1650 × 750 | 850 × 1850 × 750 | |

| Power supply | 400V – 50Hz / 16 A / 400V – 50Hz / 16 A / 400V – 50Hz / 32 A | |||

| Weight | approx. 420 kg | approx. 478kg | approx. 530 kg | |

* Data may vary

** Optional equipment

*** Expandable on request

² Approx. 400 KB (500 steps incl. comments)

³ Valid if spindle speed × feed < 3600/min

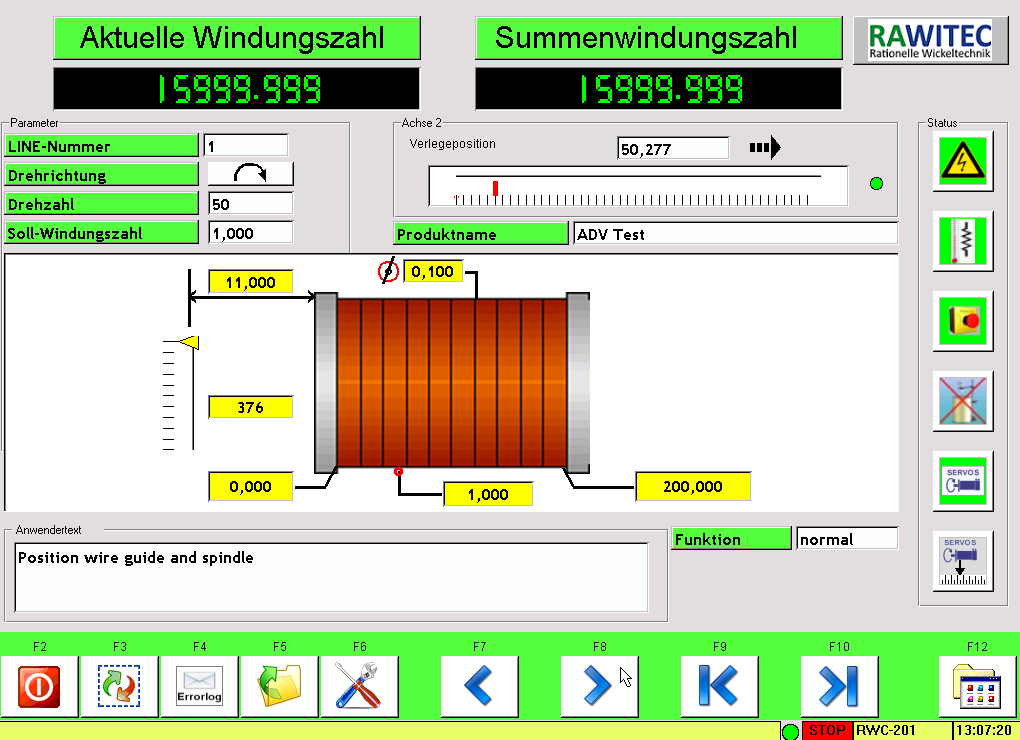

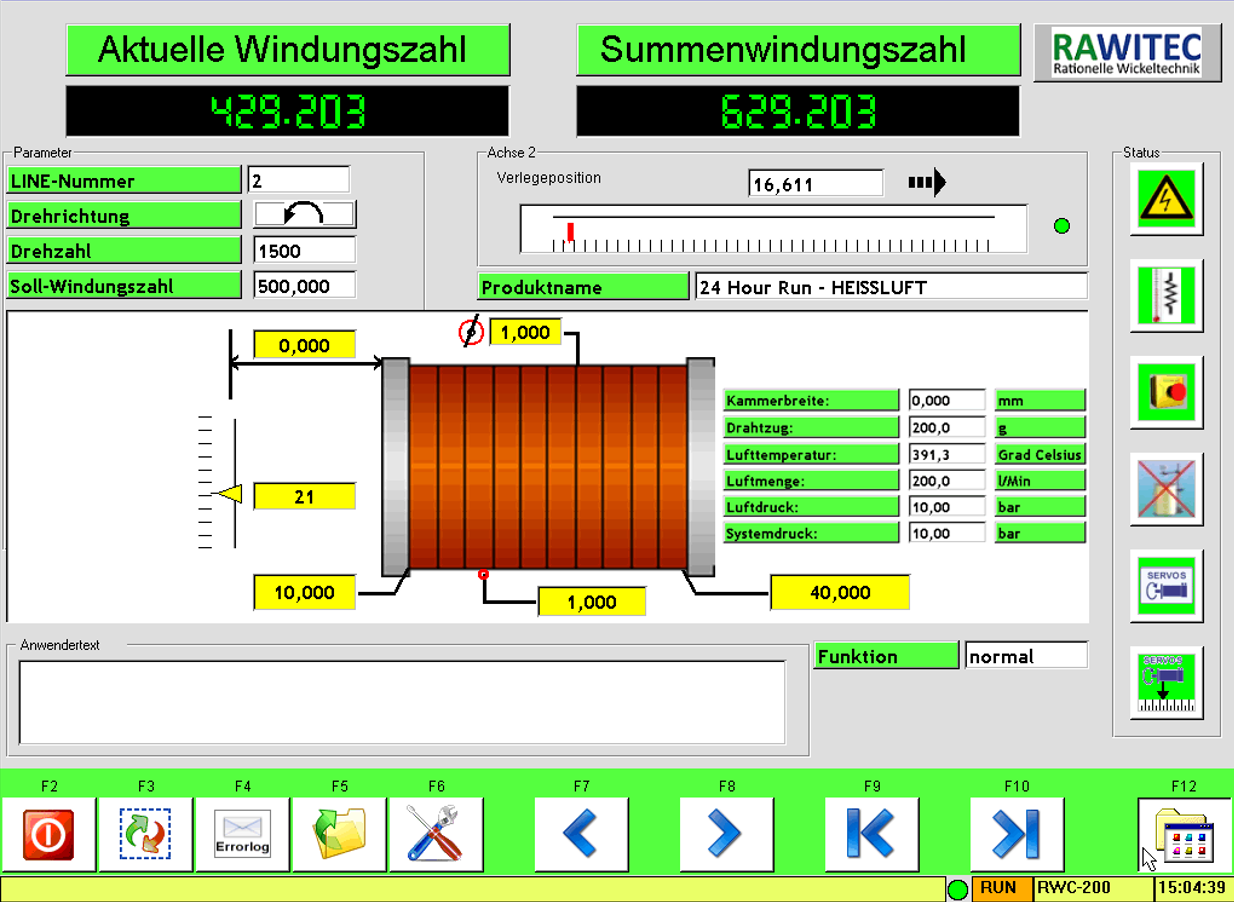

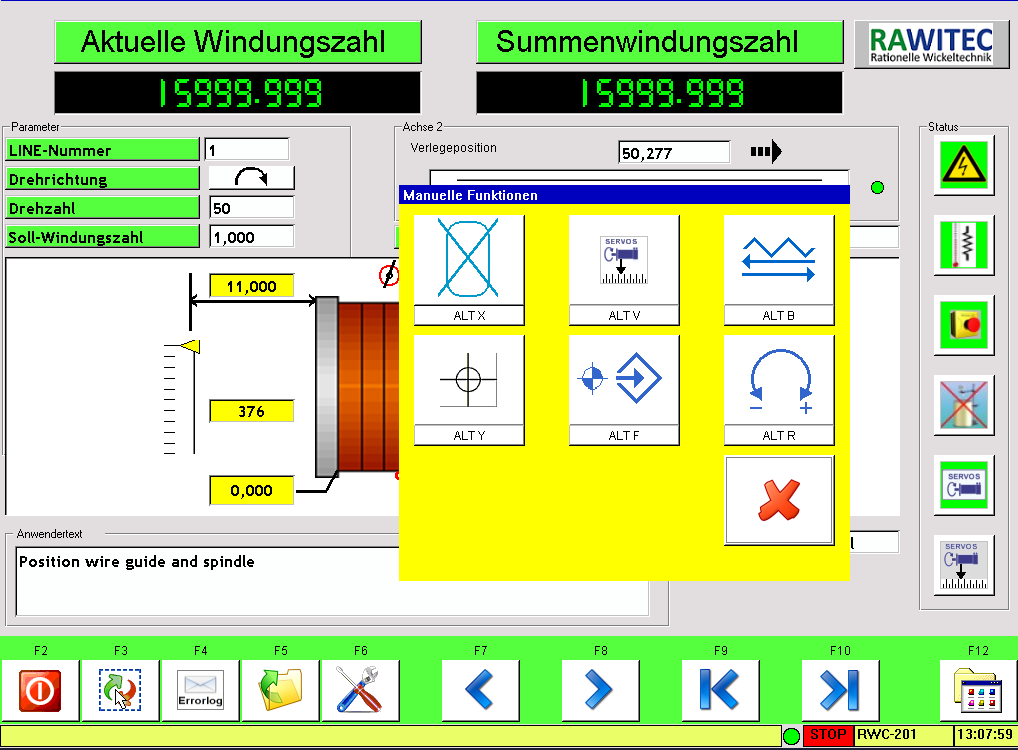

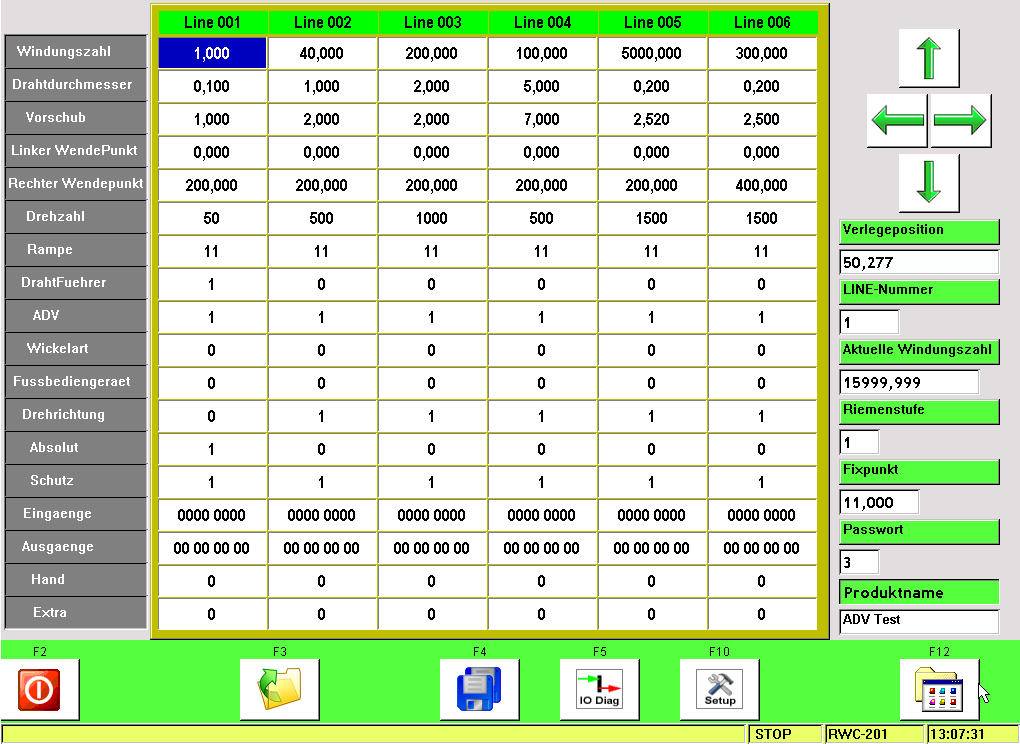

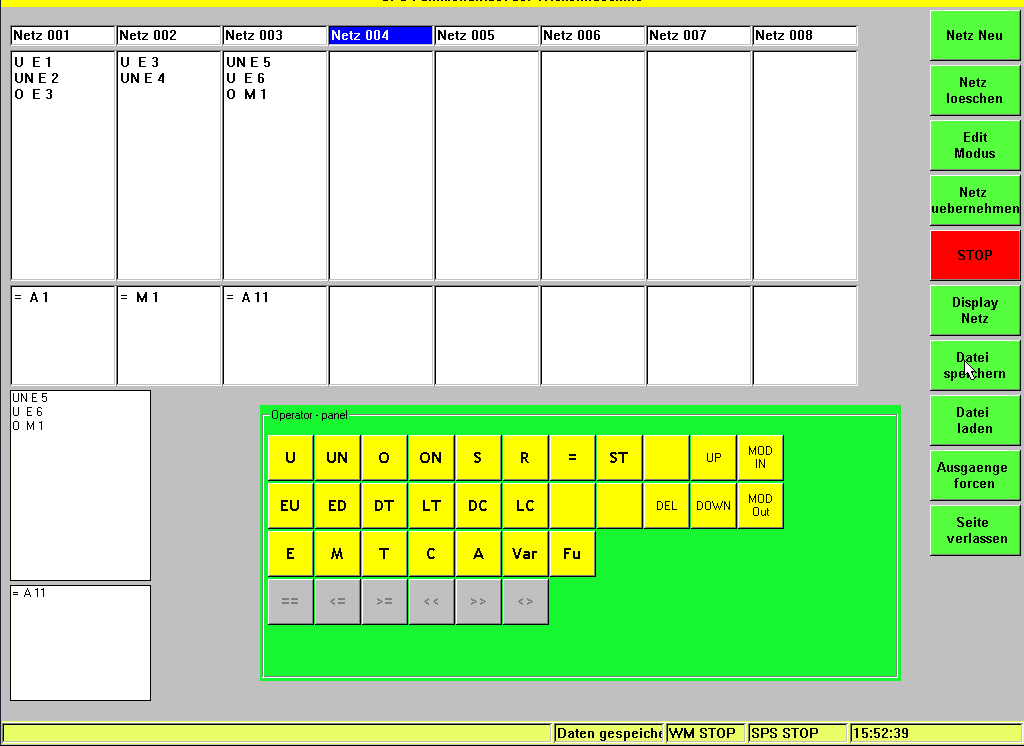

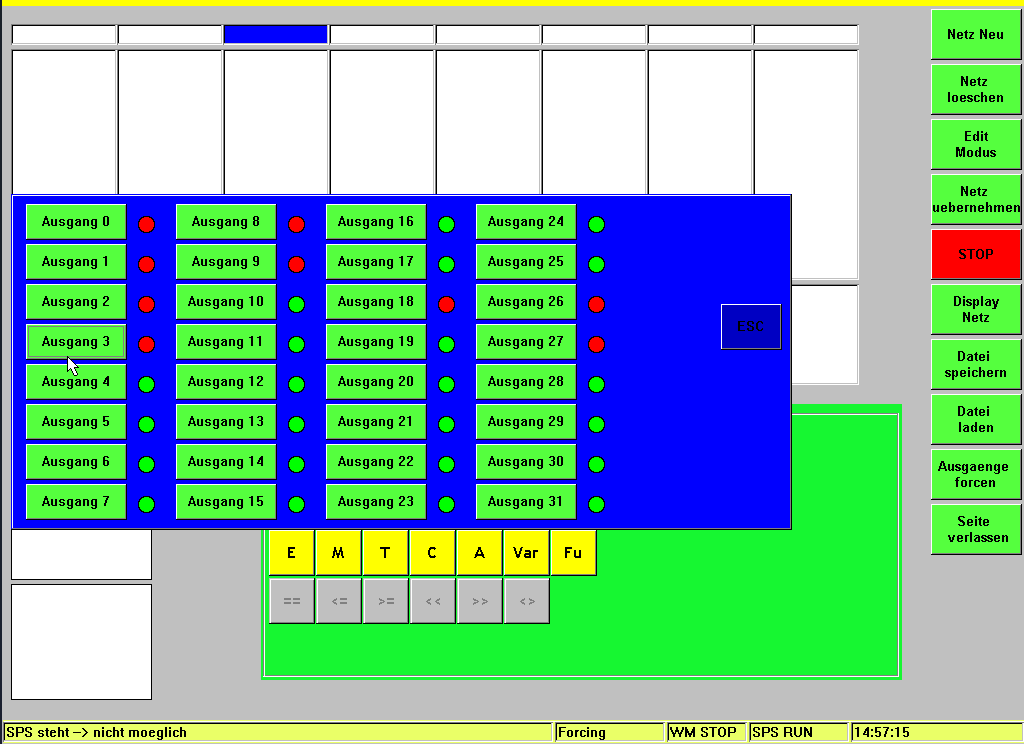

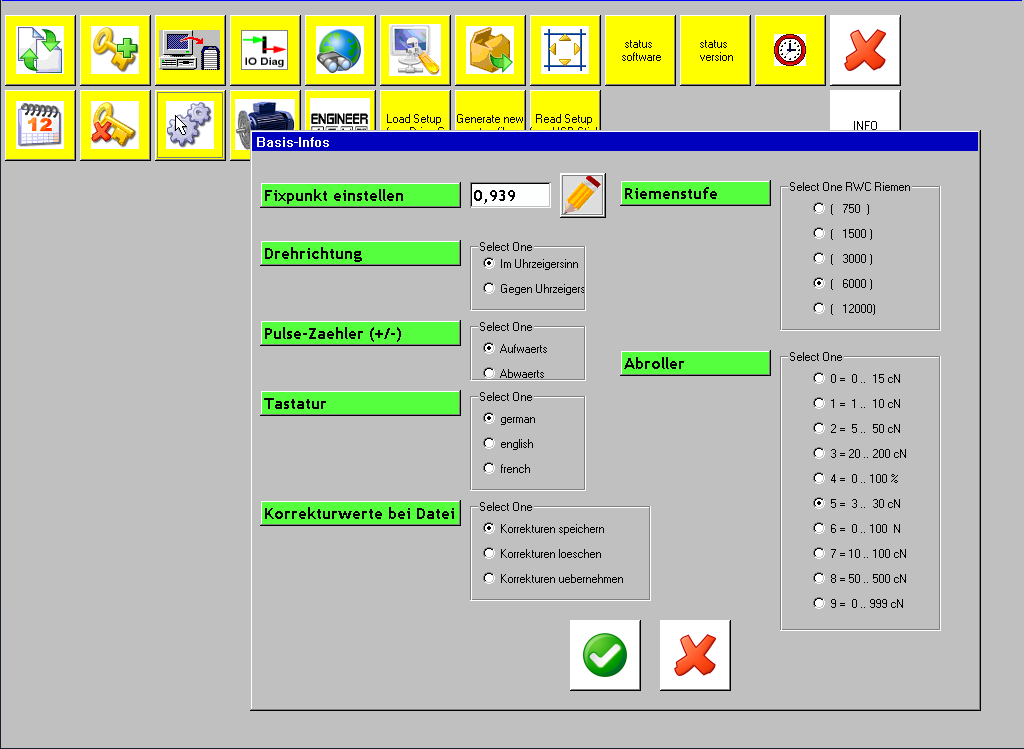

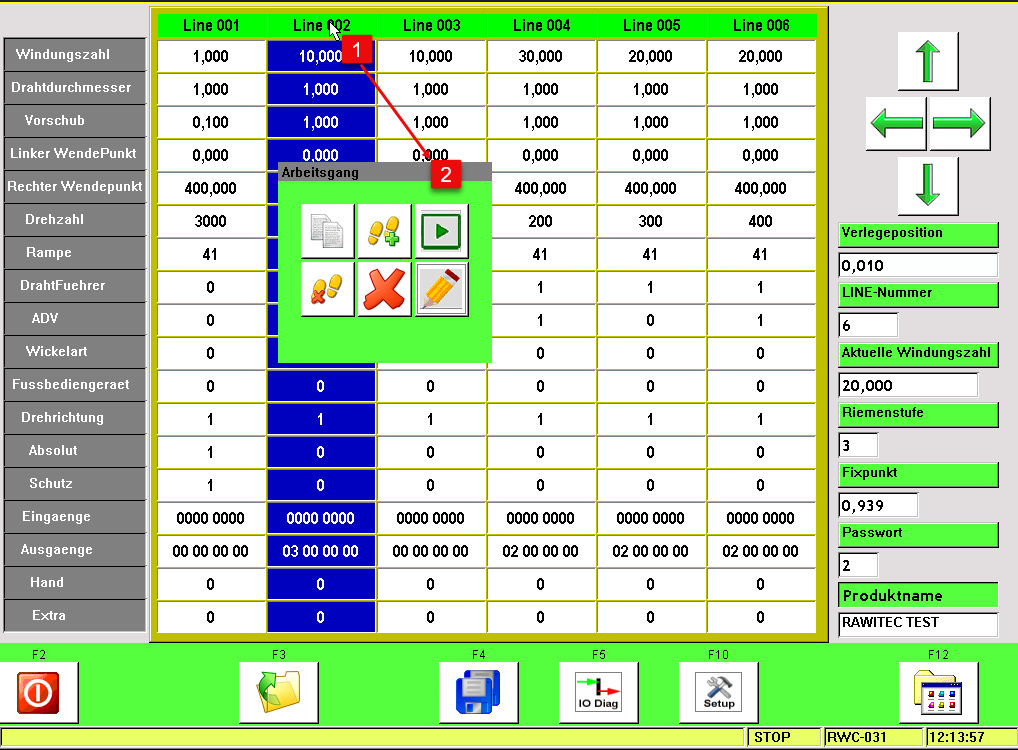

Intuitive Touch Software for Winding Machines – Powerful & Versatile

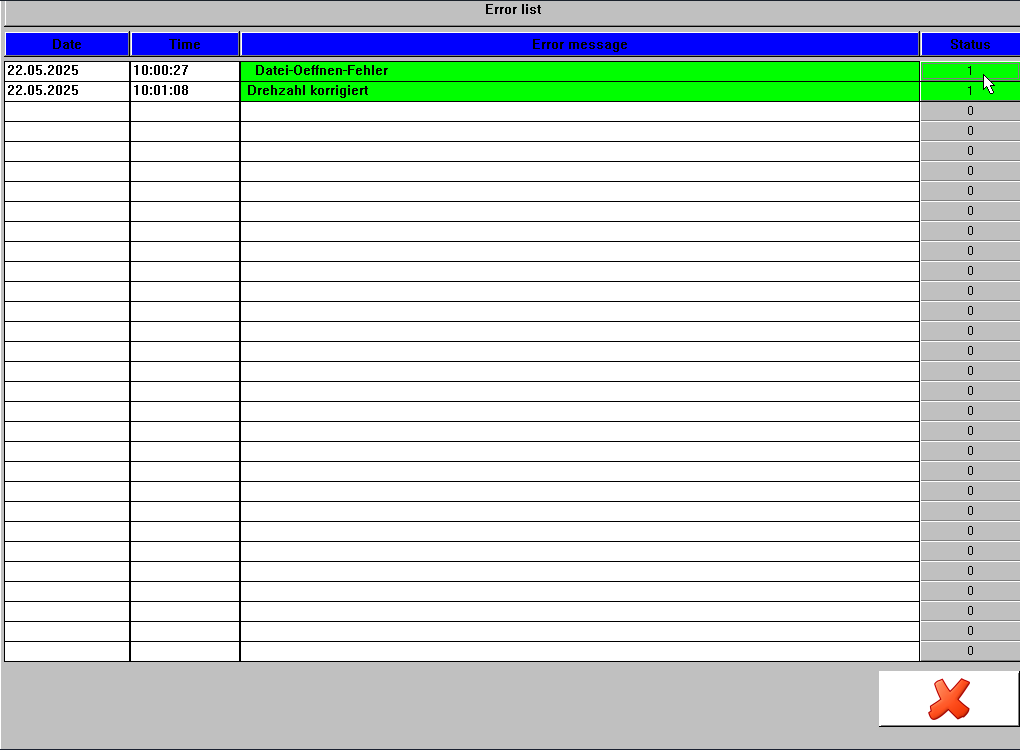

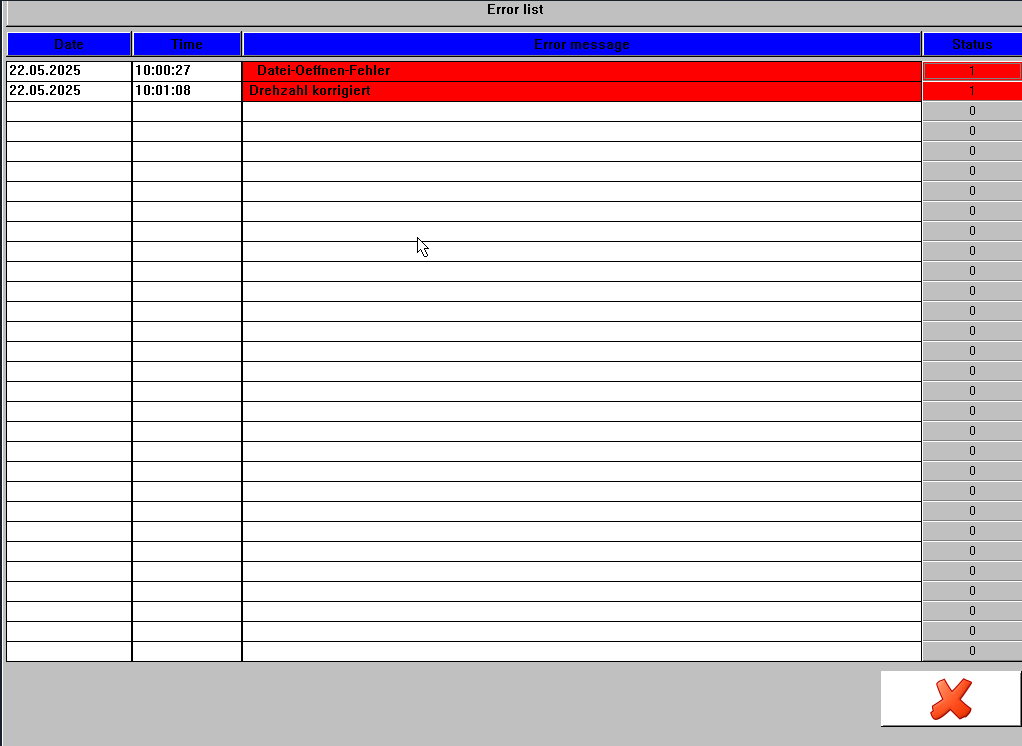

The user interface was specially developed for intuitive and efficient touch operation on winding machines.

In addition to essential functions such as Open, Save, Copy, Delete, Edit, and Print winding programs, the software offers numerous advanced features:

- Integrated language switch for international use

- Extensive configuration options

- Service-relevant diagnostic tools

- Tools for system optimization and machine customization

Thanks to its clearly structured interface, the software supports both machine operators in daily production and technical staff during machine configuration and customization.

🔧 Dynamic Working Lines – RWC301

The adjacent diagram illustrates the relationship between the winding radius and the resulting wire tension force under various operating conditions of the RWC 301 winding machine.

As the winding radius increases – meaning the spool diameter becomes larger – the force at the winding axis decreases. The physical principle is simple:

Power = Torque × Speed

Since the machine's power remains constant, the torque decreases as speed increases – and with it, the achievable wire tension force.

📊 Timing Belt Comparison Table – RWC301-S / RWC301-V / RWC301-V2

| Belt Set | Speed (RPM) | RWC301-S | RWC301-V | RWC301-V2 | Description |

|---|---|---|---|---|---|

| 0 | 750 | 50.4 Nm | 64.0 Nm | 80.0 Nm | Maximum torque – for large coils and high pulling forces |

| 1 | 1500 | 25.2 Nm | 32.0 Nm | 40.0 Nm | Balanced setup – standard for wide range of applications |

| 2 | 3000 | 12.6 Nm | 16.0 Nm | 20.0 Nm | Direct drive – nominal speed of the AC servo motor |

| 3 | 6000 | 6.3 Nm | – | – | High speed – ideal for smaller wire diameters |

📈 Diagram Interpretation

- The colored lines represent the wire tension [N] depending on the winding radius [mm] for models RWC 301-S, RWC 301-V, and RWC 301-V2.

- The left Y-axis is logarithmically scaled to show both low and high tension forces clearly.

- The right Y-axis shows typical wire diameters [mm] as a reference for wire selection.

- The larger the winding radius, the lower the resulting force – which influences the drive configuration choice.

🧩 Practical Application

This graphic makes it easier to choose the right drive configuration:

- Adjustment to wire diameter (e.g. 0.25 mm vs. 3.0 mm)

- Consideration of the required tension range

- Depending on the desired winding speed

- Optimized for the respective spool diameter

The RWC 301 can thus be optimally adapted to various applications in sensor and transformer manufacturing.

🔎 Note: For machines with two spindles, the effective torque per spindle is halved. The actual wire tension also depends on the wire brake and may vary accordingly.

RWC 301-R – High-Torque Winding System for Demanding Wire Applications

The RWC 301-R is a high-performance winding machine equipped with powerful AC servo drives (5 to 6.24 kW),

built for precision and mechanical strength. It is particularly suited for heavy-duty winding tasks with large wire diameters – while also

handling fine wires from approx. 0.3 mm upwards.

Depending on the winding diameter and wire brake force, the system supports wire diameters of approx. 0.3 to 7 mm.

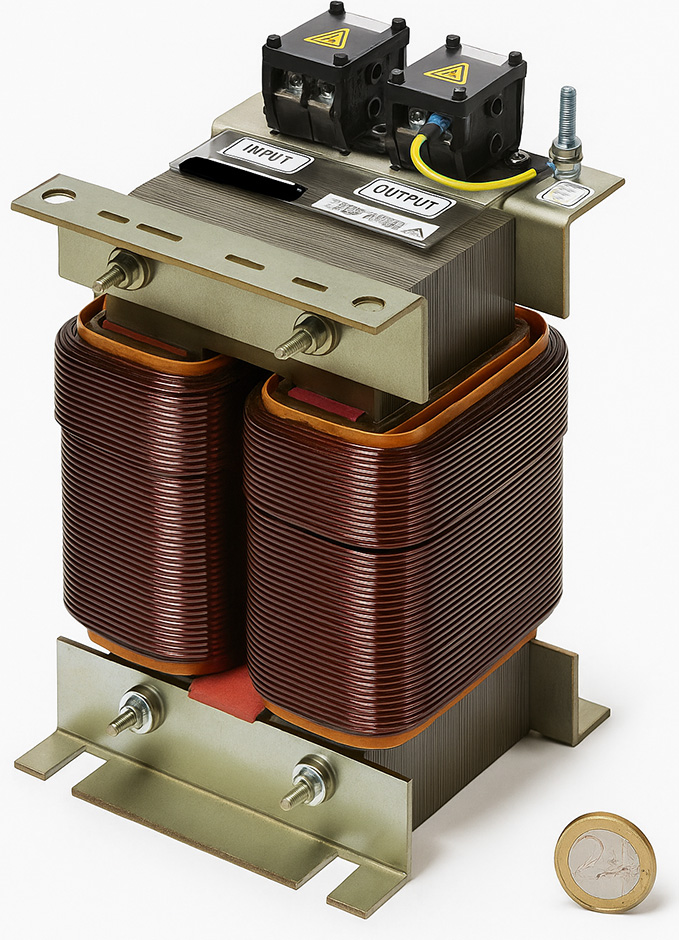

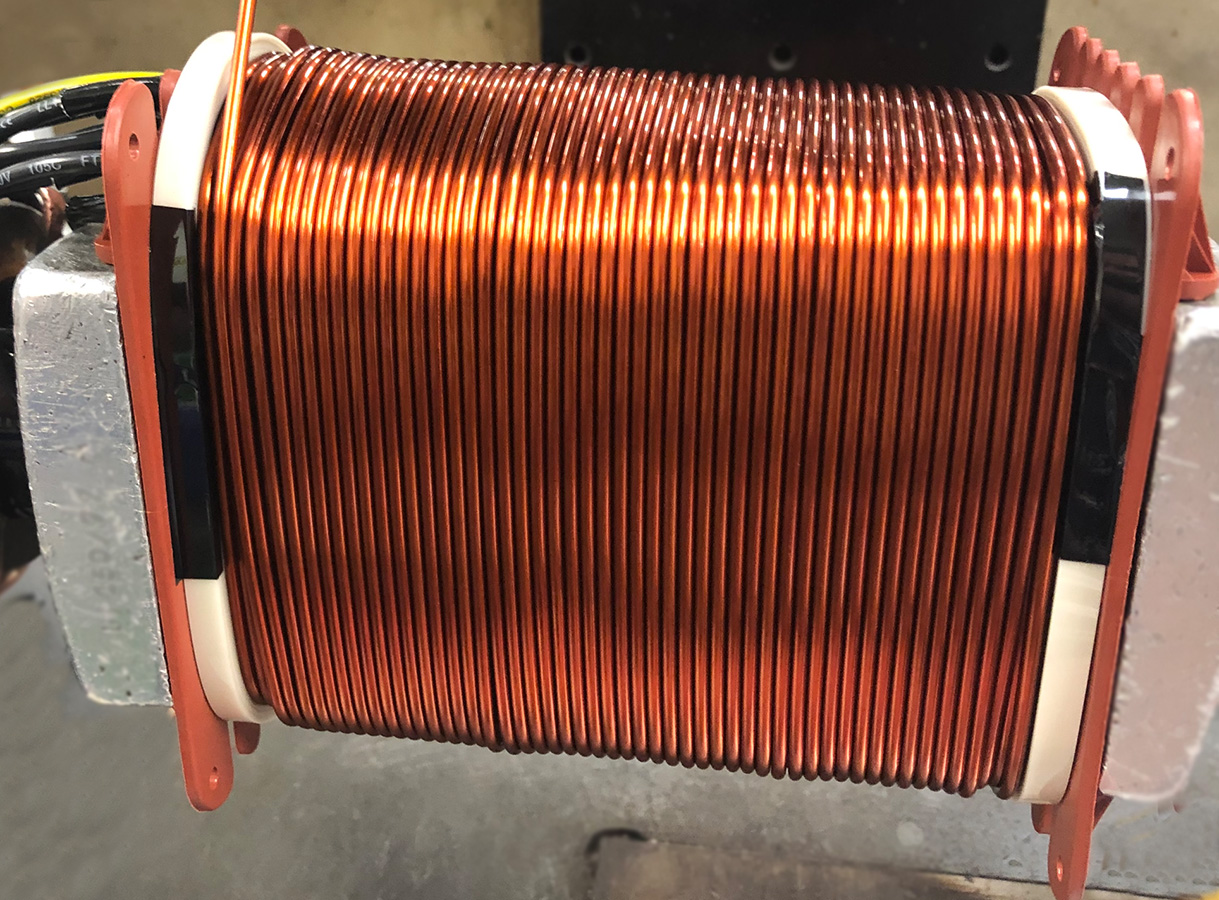

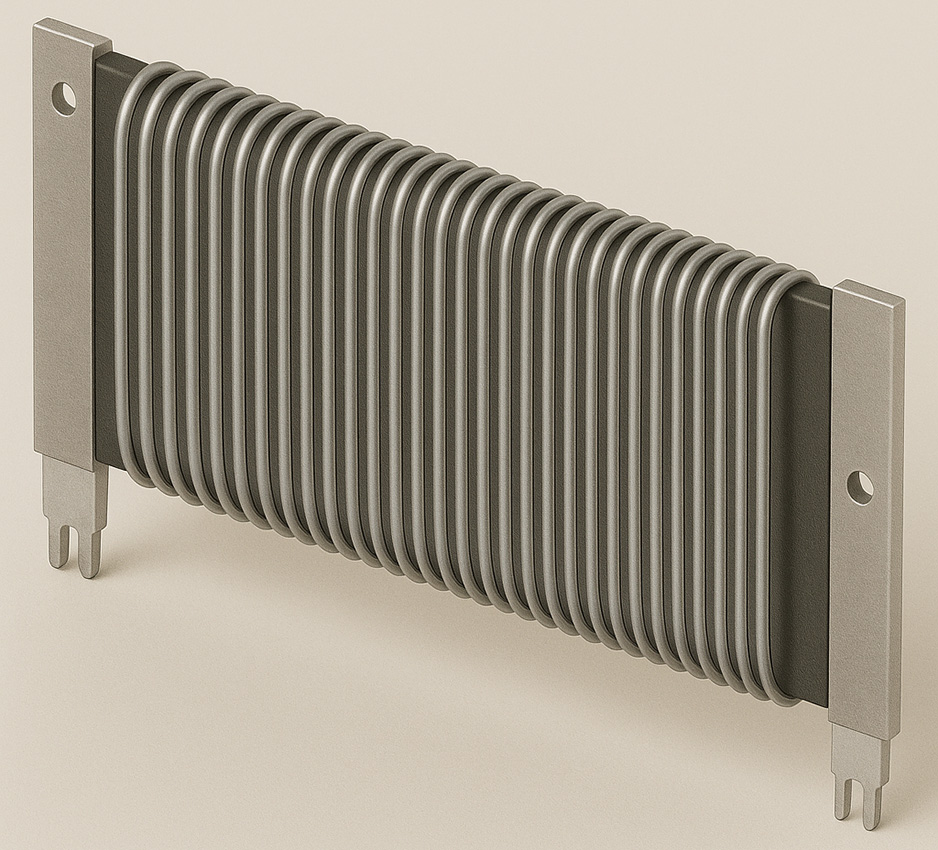

🧩 Typical Applications

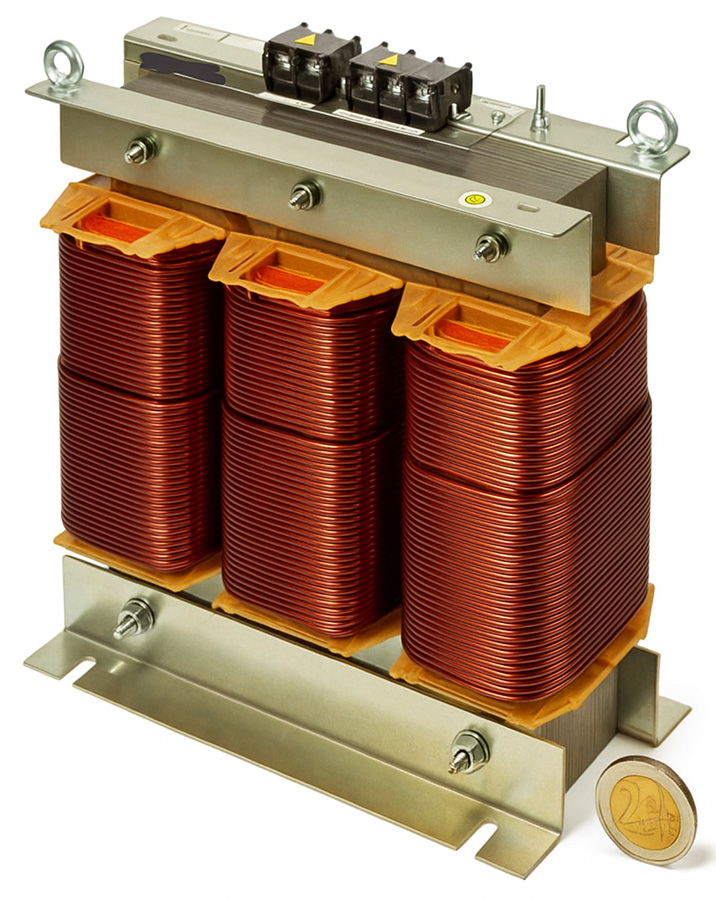

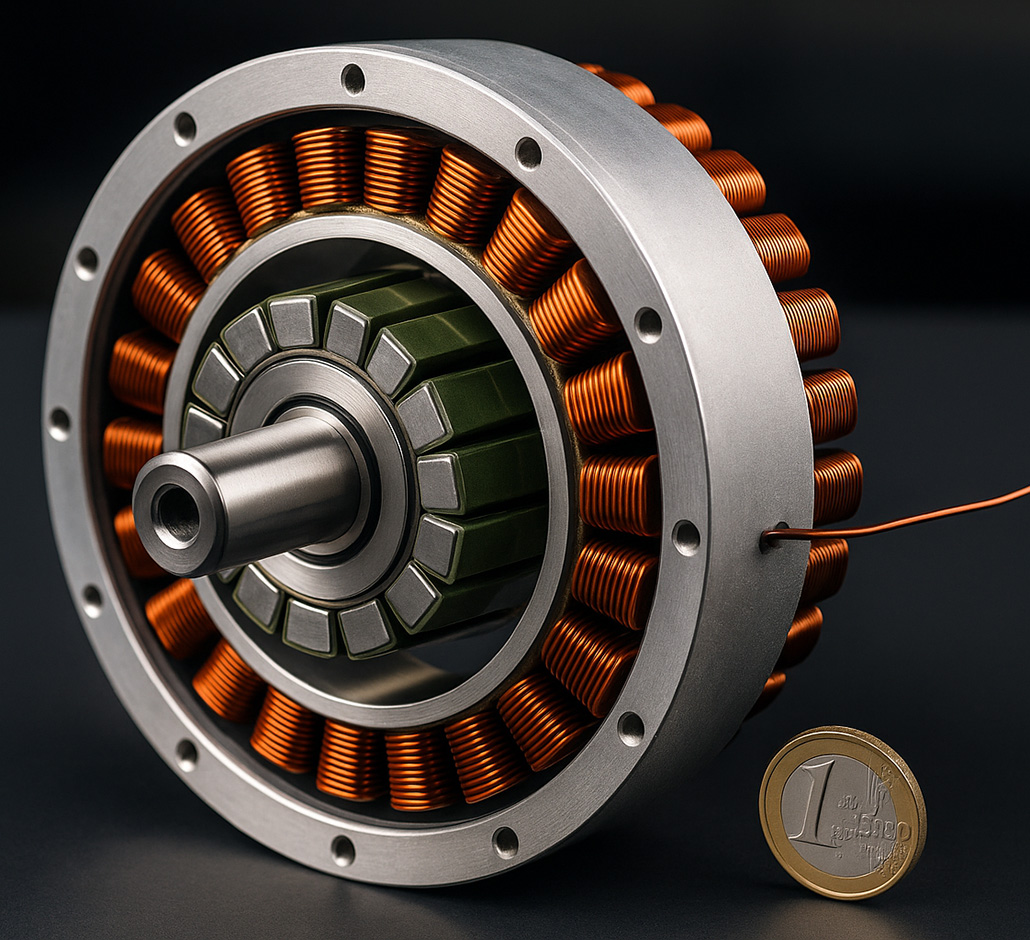

- 🔥 Heavy-duty windings: heating coils, brake resistors

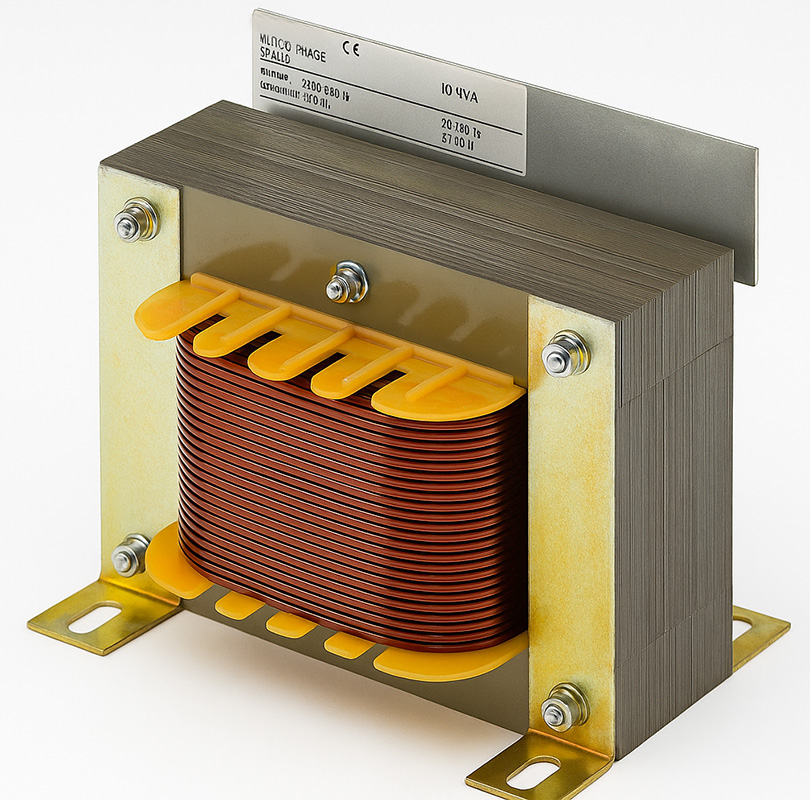

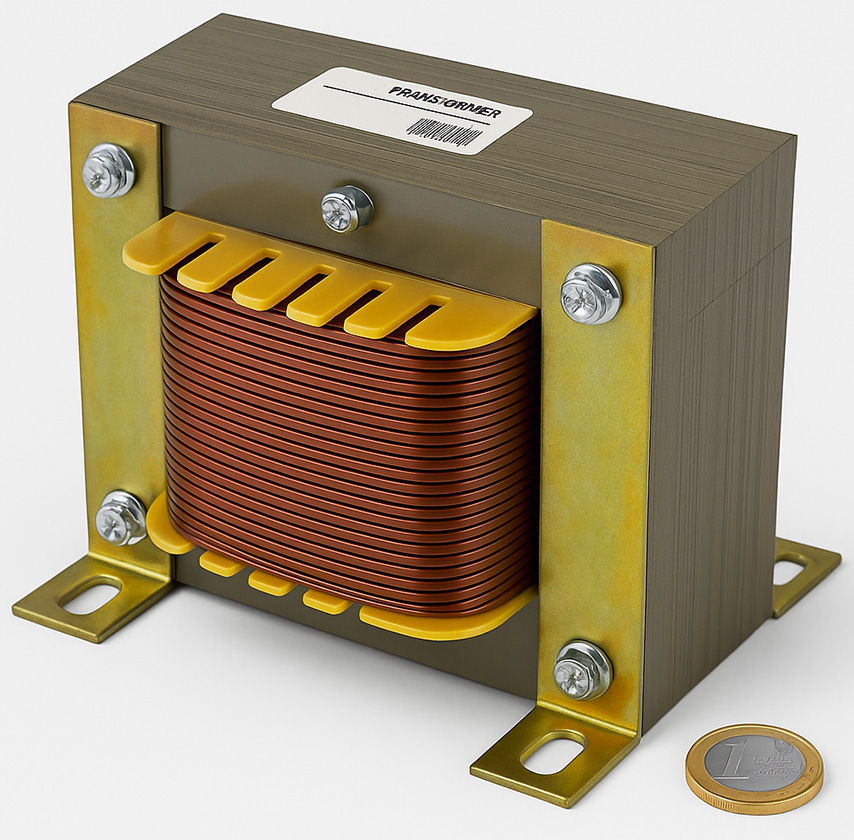

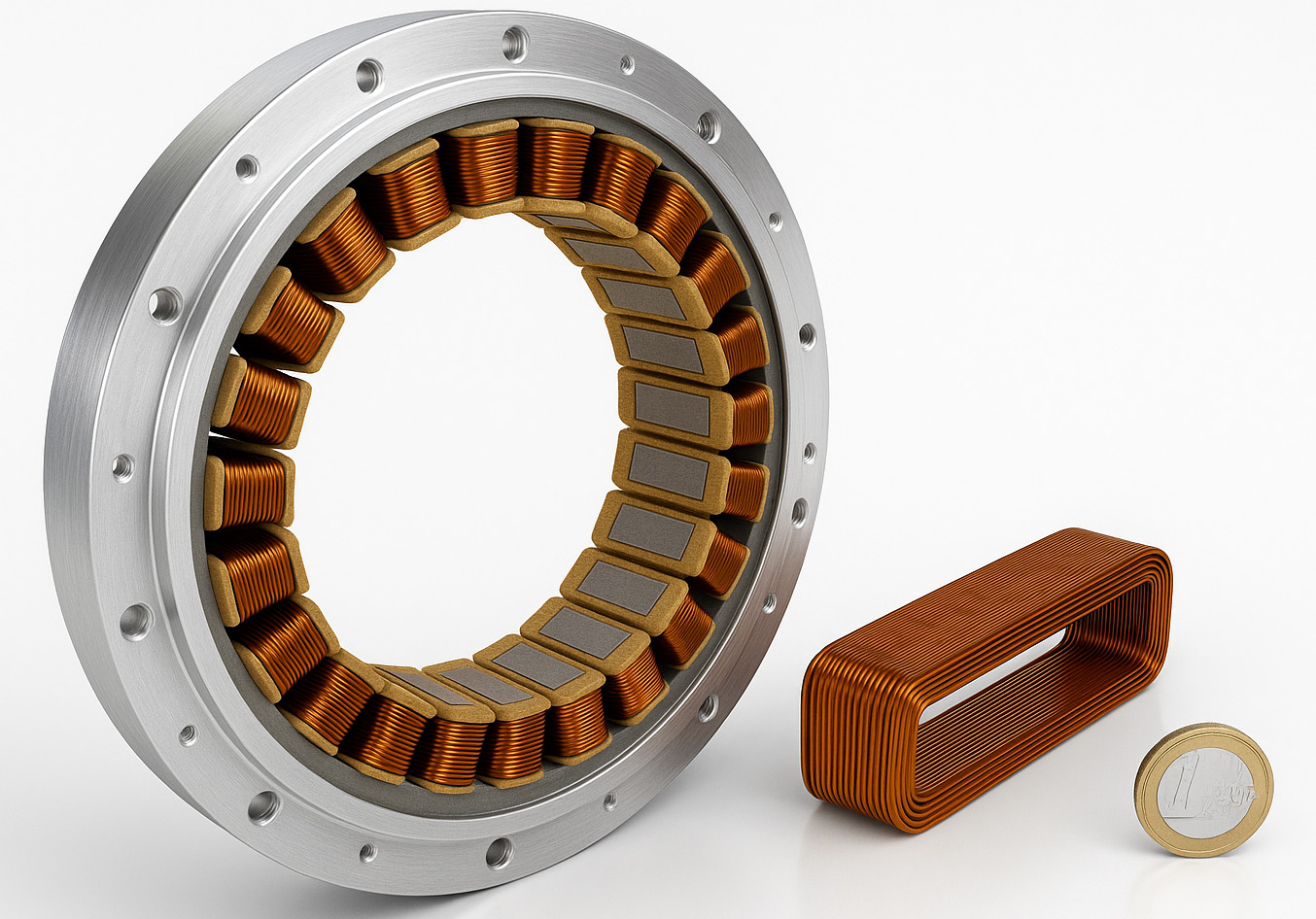

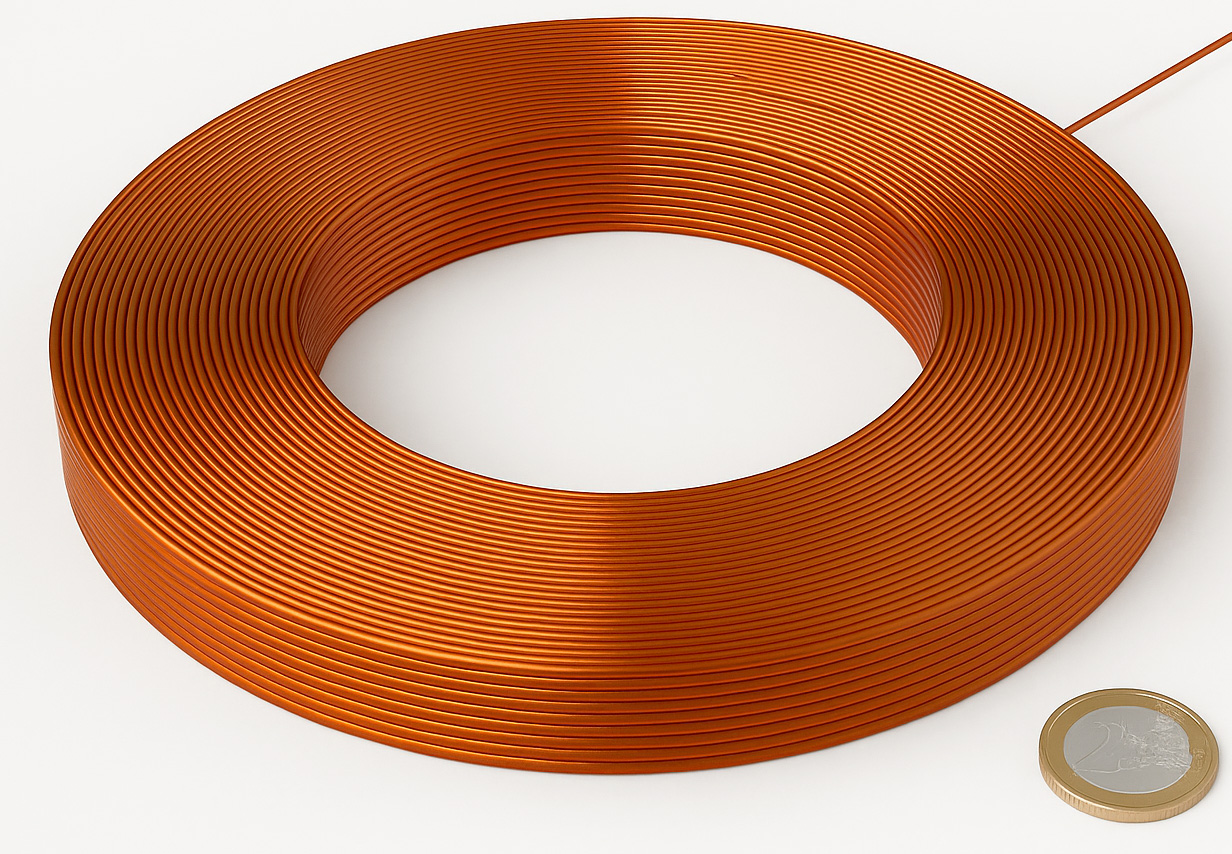

- 🔄 Flat wire windings for transformers and power inductors

- 🔬 Micro-coils for sensors, medical devices, or hearing aids

- 📡 Inductive components for wireless charging systems

- 🧪 Customized geometries and prototyping for R&D

✅ Key Advantages

- 💪 High-torque AC servomotors for strong wire control

- 📏 Wide wire range: approx. 0.3 mm to 7 mm

- 🏭 Rugged design for industrial production (single or series)

- 🎛️ Intuitive interface and flexible parameter settings

- 🧱 Modular expandability for advanced requirements

🚀 With the RWC 301-R, you benefit from maximum flexibility and power – from high-tension flat wire windings to delicate precision coils for high-tech applications.